DPM3 User Manual, 1st Edition

User Manual - DPM3 Series Panel Meters

15

Process input

The DPM3 is designed to measure all kinds of process variable with direct indication in

engineering units.

The parameter to configure as process indicator is the input type, in volts in a -10 V to 10 V

range and in milliamperes in a -20 mA to 20 mA range.

Load cell input

Refer to cell manufacturers documentation, particularly with respect to the cell sensitivity and

supply voltage specifications.

As load cell indicator the meters function is to measure forces (weight, pressure, torque...) when

connected to several bridge type transducers such as load cell, which supply signal levels up

to ±150 mV. The excitation voltage supplied by this instrument is 10V. Up to 2 cells can be

connected in parallel with 10 V excitation without need for an external source.

Example:

2 cells with 2 mV/V sensibility are supplied with an excitation voltage of 10 V; the

voltage generated by each cell at full load is 20 mV, being 20 mV the maximum as the

cells are connected in parallel.

Configuration requires selection of the input range which may be selected high enough for the

maximum input signal to avoid overloads. There are three ranges: ±15 mV, ±30 mV and ±150

mV

Example:

If a weighing process gives 12 mV to the meter input with maximum load, the best input range

to select will be “15 mV”.

Pt100 RTD Input

When configuring the meter as thermometer for 3 wires Pt100 sensors, the temperature ranges

and resolution available are:

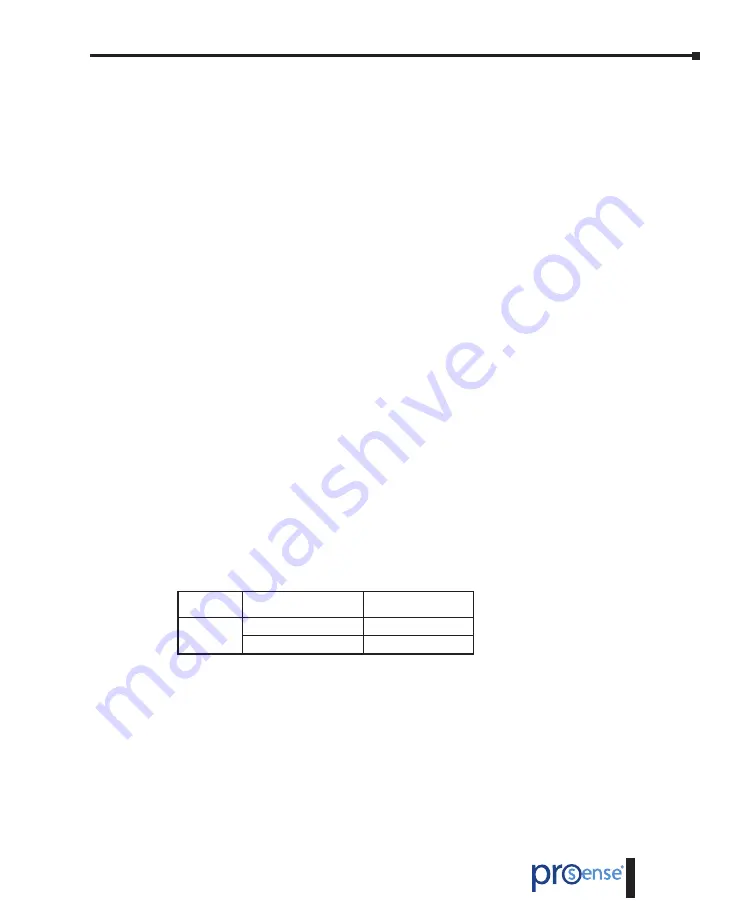

Input

Range (res. 0.1°)

Range (res. 1°)

Pt100

-200.0 to +800.0°C

-200 to +800°C

-328.0 to 1472.0°F

-328 to 1472°F

The Pt100 software menu allows selection of temperature units (Celsius or Fahrenheit),

resolution (degree or tenth of degrees) and a display offset. Offset value is programmed for a

known difference between the temperature under measurement and the temperature read by the

sensor. This difference can be corrected by programming an offset from -19.9 to +99.9.

LED

TARE will light up each time that an offset value is programmed.

Example:

In a process of temperature control the Pt100 sensor is located in a part of the process

where temperature is 10 degrees below than the point where the control has to be done. By

programming an offset of 10 points, with 1 degree resolution, the deviation will be corrected.

Configurable parameters for this input are: