11

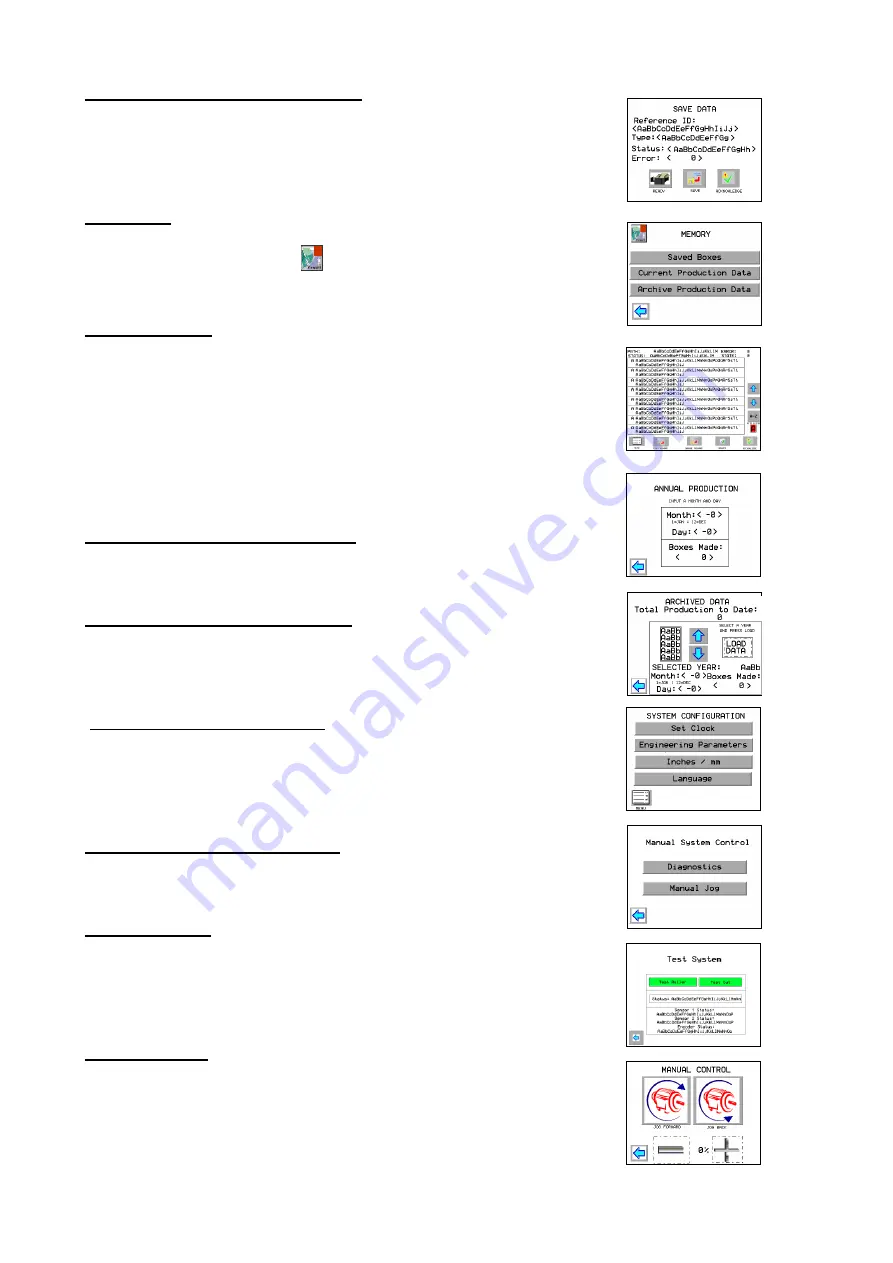

SAVING BOXES INTO MEMORY

Touching ‘Save’ will allow the current box to be entered into the

memory for future use.

The virtual alpha-numeric keyboard can be used to give each box a

code, or name, for identification.

MEMORY

The memory can be accessed via the main menu or from other

screens by touching the

button.

SAVED BOXES

Touch ‘Saved Boxes’ button to display the list of saved boxes.

These will be saved in alphanumeric order. To reduce the search

time, touch the ‘Goto’ button and enter a letter on the keyboard

that will appear on screen. The cursor will jump to the section

starting with that letter.

Use the up/down arrows to move the cursor to the box required

and touch the ‘Run Program’ button.

Set the guide, prepare the blanks and the machine is ready to use.

CURRENT PRODUCTION DATA

Enter a month and day to recall the number of boxes made on that

day.

ARCHIVE PRODUCTION DATA

At the beginning of each year, the previous year’s production can

Be recorded into the permanent memory. The total number of boxes

produced to date is also displayed.

SYSTEM CONFIGURATION

Touch ‘Configure System’ on main menu.

This screen allows the operator to set the time and date, change

from inches to millimetres and select language.

Engineering parameters are protected by a password.

MANUAL SYSTEM CONTROL

Select ‘Manual Control’ from main menu.

DIAGNOSTICS

Touch and hold the ‘Test Roller’ button to run the board feed roller

or ‘Test Cut’ to operate the blade.

Pushing a piece of board into the machine should operate ‘Sensor 1’,

‘Sensor2’ and ‘Encoder’ to ensure that all are functioning correctly.

MANUAL JOG

Allows the board to be fed into, or out of, the machine.

This screen will automatically appear if a board jams in the

machine. Once the board is cleared, touching the ‘back arrow’ will

return to the run screen.