10

SCREENS

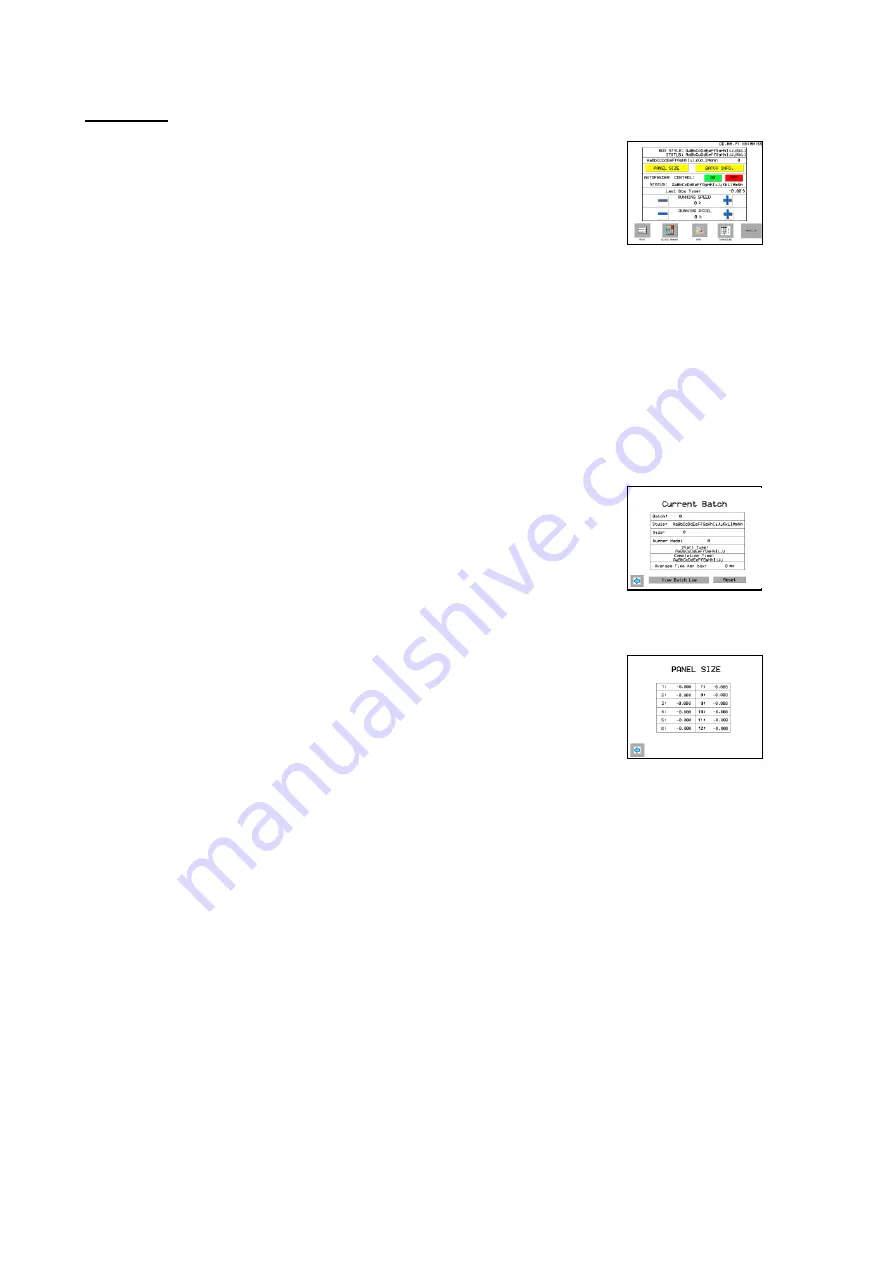

The ‘Run’ screen is displayed while making boxes. It displays the

time and date, the box style being made and the number made.

It also allows the operator to select several options including;

save the current box to memory, check the dimensions entered,

adjust the throughput speed or return to the ‘Main Menu’.

‘Running Speed’ and ‘Running Accel’ allows the operator to select the ideal throughput

speed and acceleration rate for making each box accurately and comfortably. Some

large, heavy boxes will need to be run at a slower speed just as very small boxes will

also need to be run slowly to prevent ‘snatching’. For best results, always select a slow

speed, say 20%, and then increase if possible.

‘Last Box Time’ shows the time taken for the previous box to pass through the machine.

This may be useful for batch costing or calculating accurate production times.

Selecting ‘Batch info’ allows the operator to enter the size of a batch to be run. The

‘Number Made’ will then count down from that number

until the batch is completed at ‘0’.

The start and finish times will then be recorded in the Batch Log.

To run a batch, first touch ‘Reset’ to clear the previous data, then

touch the ‘size’ to enter the number of boxes to be run.

Touching the ‘back arrow’ will return to the ‘Run’ screen.

When a batch is cleared, set up and completed in this way, it will be automatically

recorded in the ‘Batch Log’. This can be viewed at any time for a record of productivity.

‘Panel Size’ shows a list of the actual measurements of the box

panels. These include allowances based on the board thickness

entered by the operator.

To check the size of the box, measure the flat box from leading

edge to centre of first slot, then from centre of slot to centre of slot

to check subsequent panels.

‘Dimensions’ will return to the box dimensions that have been entered for confirmation

or to make changes.

‘Base/Lid’ is used when making 0300 and 0301 boxes to switch from the base to the lid

and back. The machine will always default to ‘base’ when entering the dimensions.

Switching to ‘Lid’ will increase the dimensions by the appropriate amount to fit over

the base. Note that the lid will require a larger board blank than the base.