- 1 -

Dear Customer, thank you for choosing this Atlas Filtri

®

, product, manufactured in

Italy.

The FMD-3 sludge filter is the ideal solution to resolve system issues due to particle

contamination (especially rust and sand) that form through corrosion and build-ups

during normal thermal system operation.

The magnetic filters ensure continuous boiler protection, trapping all the impurities that are in the

system, and keeping them from circulating thereby preventing the system components from being

worn and damaged (for example, circulators and heat exchangers).

TECHNICAL SPECIFICATIONS OPERATING CONDITIONS

Body: Reinforced PA66 polyamide. Compatible liquids: Water, water + glycol.

Filtering cartridge: AISI 304 L stainless steel. Max. operating pressure: 3 bar at 90°C

O-rings: EPDM. (43 psi at 194°F).

Discharge cap: CW 614 N - 3/4” brass. Operating temperature: 4÷90°C (39.2÷194°F).

Magnet: NdFeB - 4500 Gauss

Magnet holder: Polypropylene.

Breather / filler cap: CW 614 N brass.

Clip: Galvanised steel.

Filtration rate: 600 µm.

OPERATION

In the FMD-3 filter, the liquid that flows through the filtering cartridge comes into contact with the

magnet; the ferrous sludge is trapped thanks to the double effect of mechanical filtration (exerted

by the cartridge) and magnetic field (exerted by the magnet).

The effect is further amplified by varying cross-sections: the filter body has a greater diameter than

the piping so the liquid slows inside the filter and the suspended particles can be more efficiently

captured and trapped. In this way, all the magnetic (ferrous residue) and non-magnetic (algae, mud,

sand, etc.) contaminants in the system are trapped in the filter body.

INSTRUCTIONS AND USE MANUAL

- Exclusively use to treat water mains of a known quality, and in any way, only use water with a pH

between 6.5 and 9.5.

WARNING:

for uses different form those foreseen, it is mandatory to have technical consent of the

manufacturer/reseller.

ASSEMBLY AND INSTALLATION MANUAL

FMD-3 must be installed by a qualified technician.

ATTENTION:

before carrying out any installation or maintenance operation, ensure that the heating

system is isolated.

On the return circuit, at the boiler input, install FMD-3 to protect it from all impurities present in the

system, especially in the start-up phase (Diagram A).

Ensure that suitable access is given for repair and maintenance interventions.

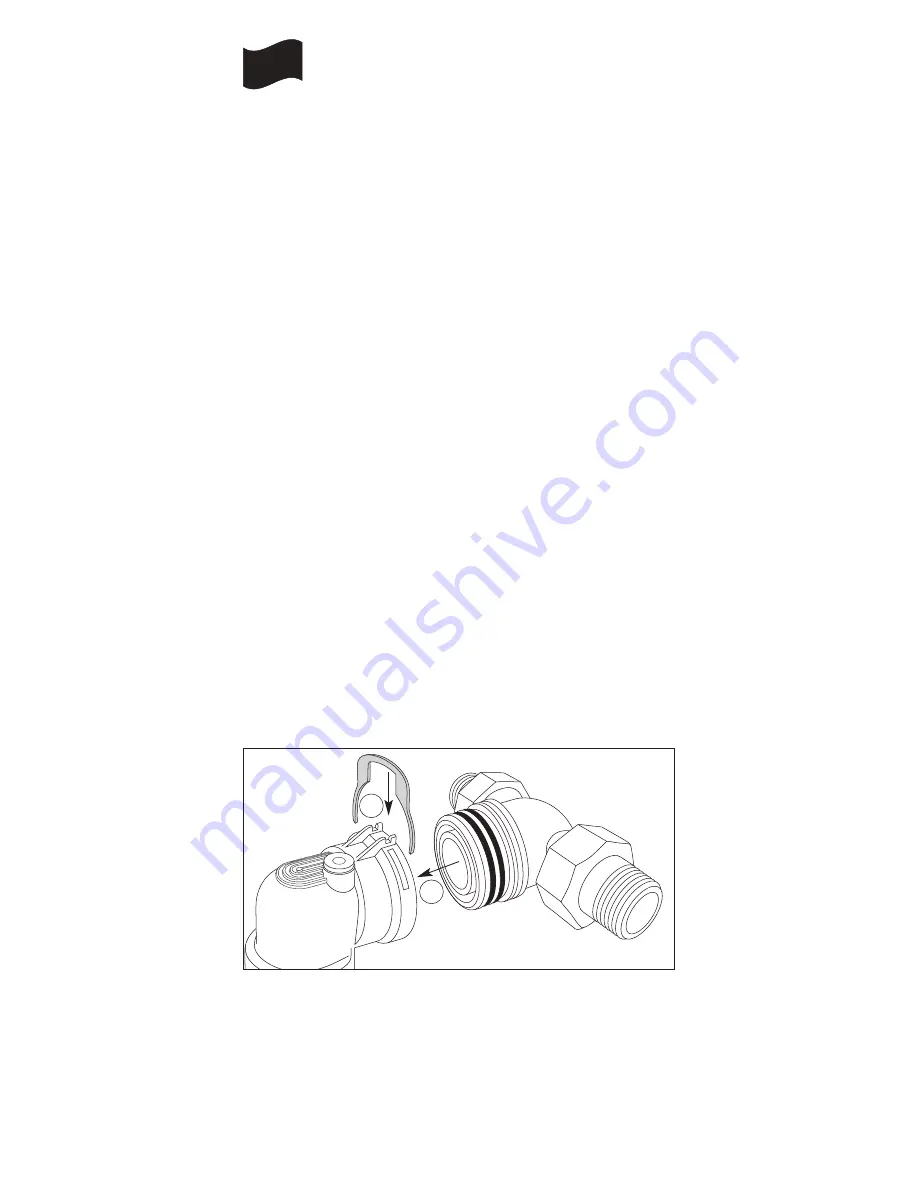

ASSEMBLING THE HEAD ON THE ADJUSTABLE T FITTING

- Properly lubricate the O-rings (only use silicone lubricants)

- Fully insert the adjustable T fitting into the head housing and slightly rotate it (rotation facilitates

insertion) (Ref. B)

- Insert the clip into the head housing; make sure it is properly inserted in the slot of the T fitting

and the head and adjustable T fitting are perfectly coupled (Ref. C)

- FDM-3 must be installed respecting the flow direction indicated by the arrow on the coupling tee

and with the body always in the upright position;

the FDM-3 swivel joint unit allows the filter

to be adapted to any piping inclination.

The special metal clip allows the filter to be quickly

disassembled. FDM-3 head is equipped with a threaded cap, which can be used both to vent and

load the system with protective/treatment chemical additives. It is advisable to install shut-off

valves on both filter fittings.

ATTENTION:

the FMD-3 filter contains strong magnets.

Always pay careful attention during installation and maintenance interventions.

Do not position the magnetic nucleus on ferrous surfaces.

ATTENTION:

use suitable protective equipment during all installation and maintenance operations.

ATTENTION:

to avoid damage due to frost, avoid installation in areas where the temperatures may

fall below 0°C.

gb

C

B