- 82 -

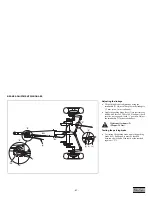

BRAKE ADJUSTMENT WAGON WITHOUT ABS

Adjusting the linkage

The parking brake is adjusted by using the

turnbuckle (1). Adjust till the play in the linkage is

1-3 mm (max. 3 mm is allowed).

Apply the parking brake lever (3) several times by

hand with a force of 200 to 300 N and put it back

into the -not engaged- tooth “1” position. Adjust

the turnbuckle (1) as described above.

Testing the parking brake

For testing the parking brake, apply the parking

brake lever. Brake power must be reached

between the 6th and 14th tooth of the toothed

segment (“Z”).

(3)

"Z"

"Y"

"Y"

(2)

(2)

(1)

"Z"

"14"

"6"

"1"

Tighten all lock nuts (2)

(Torque: 24 Nm).

Summary of Contents for XAHS 447 Cd S3A APP

Page 2: ......

Page 24: ... 24 SH 03 ENGINE CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 25: ... 25 SH 04 CONTROL MODULE 1 2 3 5 9 8 7 6 4 10 A B C D 9822 0963 49 ...

Page 26: ... 26 SH 05 COMPRESSOR CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 27: ... 27 SH 06 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 28: ... 28 SH 07 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 4 10 A B C D E 9822 0963 49 ...

Page 110: ... 110 Notes ...

Page 111: ......

Page 112: ......