- 68 -

COMPRESSOR OIL FLUSHING PROCEDURE

To avoid problems when changing over to a new type

of oil (see table) a special Compressor Oil Flushing

Procedure has to be followed. The procedure is only

valid in case the replaced oil has not exceeded its

lifetime. For more information consult Atlas Copco

Service dept.

Aged oil can be recognized best by using an oil

sampling analysis program. Indicators for aged oil are

strong smell, or contamination such as sludge and

varnish inside the oil vessel and oil stop valve or a

brownish colour of the oil.

Whenever aged oil is discovered, eg. when changing

the oil separator, contact Atlas Copco Service dept. to

have your compressor cleaned and flushed.

1. First thoroughly drain the system when the oil is

warm, leaving as little oil in the system as

possible, especially in dead areas, if possible blow

out remaining oil by pressurising the oil system.

Check the instruction manual for detailed

description.

2. Remove the compressor oil filter(s).

3. Open the oil vessel and remove the oil separator

element.

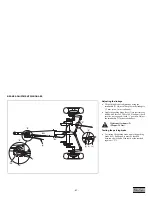

4. Check the interior of the oil vessel (see pictures).

If varnish deposits are discovered, contact Atlas

Copco Service dept. and do not continue.

5. Put in a new oil separator, screw on new

compressor oil filter(s) and close the oil vessel

according to the instructions.

6. Fill the oil vessel with the minimum amount of

replacement oil, run the compressor under light

load conditions for 30 minutes.

7. Thoroughly drain the system when the oil is

warm, leaving as little oil in the system as

possible, especially in dead areas, if possible blow

out remaining oil by pressurising the oil.

8. Fill the system with the final oil charge.

9. Run the compressor under light load conditions

for 15 minutes and check for leakage.

10. Check the oil level and top up if necessary.

11. Collect all waste lubricant used during the

flushing process and dispose of it in accordance

with the applicable procedures for managing

waste lubricant.

Vessel cover

contaminated

clean

Vessel

contaminated

clean

Not respecting compressor oil changing

intervals in accordance with the

maintenance schedule, can lead to

serious problems, including fire hazard!

The manufacturer does not accept any

liability for damage arising from not

following the maintenance schedule or

not using genuine parts.

Instructions on replacing the oil

separator element are available from

Atlas Copco Service dept.

*

When changing over to the same oil within the oil changing interval, draining is sufficient

** Change over not recommended

PAROIL M

PAROIL S

PAROIL S xtreme

PAROIL M

draining *

flushing

flushing

PAROIL S

draining **

draining *

draining

PAROIL S xtreme

draining **

draining

draining *

Summary of Contents for XAHS 447 Cd S3A APP

Page 2: ......

Page 24: ... 24 SH 03 ENGINE CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 25: ... 25 SH 04 CONTROL MODULE 1 2 3 5 9 8 7 6 4 10 A B C D 9822 0963 49 ...

Page 26: ... 26 SH 05 COMPRESSOR CIRCUIT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 27: ... 27 SH 06 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 G 4 10 A B C D E F 9822 0963 49 ...

Page 28: ... 28 SH 07 OPTIONAL EQUIPMENT 1 2 3 5 9 8 7 6 4 10 A B C D E 9822 0963 49 ...

Page 110: ... 110 Notes ...

Page 111: ......

Page 112: ......