15

Fault diagnostic / Troubleshooting

Only the green

Power

LED should light up with the correct wiring and switching-on of the voltage

supply. If one of the other LED’s light up then there is an error in the system which can be localized

by the LED’s.

If the fault is not in the wiring, verify the function of the electronics by applying an 8.2 k

Ω

resistor to

the X1/X2 input of the safety controller. If the electronics work correctly thereafter, the PSS must be

checked by using a resistor measuring instrument (Ohmmeter). For this, the connection between the

safety controller and the PSS must be disconnected, and the PSS must be connected to the measuring

instrument. The resistor value must be 8.2 k

Ω ±

100

Ω

for a not operated PSS, and in the operated

condition the value should not exceed 500

Ω

.

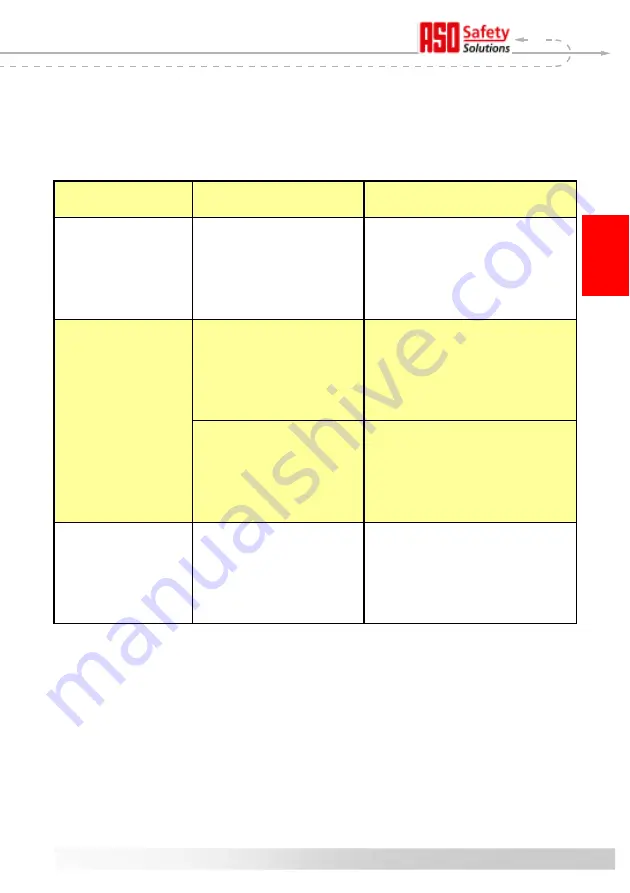

LED

Fault

Fault rectification

LED's do not light up

Supply voltage is failing, to low

or wrongly connected

Verify the connections and the supply

voltage:

A1 A2: 12-24 V AC/DC

toleranz range: +10%

L1,N,PE: 230 V AC 50-60Hz

Connecting cables of the PSS

or the PSS itself is faulty

Verify the connections, the wiring and

the connecting cables of the PSS

(crushed cables, brittle cables etc.).

Verify the PSS*

Testing is faulty

Verify the the Dip-slide switch position.

Verify and/or adapt the test-signal of

the machinery control system / PLC

and switch the Dip-slide switch in the

correct position.

LED Fault lights up

Connecting cables of the PSS

or the PSS itself is faulty

Verify the connections, the wiring and

the connecting cables of the PSS

(crushed cables, brittle cables etc.).

Verify the PSS*

LED Actuate lights up

English

*