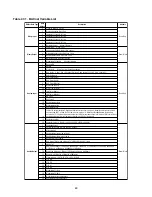

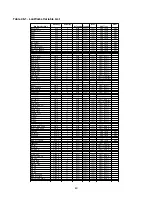

Item No.

Water Compartment

Part No.

—

PVC Tubing 5/8"

A7618A

—

Clamp Hose Flat .63 Olive

B2716-11

—

Hose Clamp, Minerature, Worm

B2911-8

25

Kit Fill Valve Assy HC-6100 and

HC-6300 Tap Water

A23520

21

Tubing Rd 5/8" I.D. Silicon

A19699

22

Tee Barbed HDPE 5/8

A23237

24

Elbow Barbed 5/8

A10579

27

Fill Cup for Series HC-6000

RDHC6000-038

27

Bracket For Fill Cup

B2929

28

Bracket for Liquid Level

B5135

28

Brkt HC-6000 Liquid Level

A22010

20

Drain Valve

B2004C

18

Drain Cup

RDEHU305-2021

17

Reducing Bushing Brass 1"-1/2"

RDHC6000-041

30

Probe Level Assy Tap

C4561

29

Container For Probe Level

C4559

—

Long Probe For Water Level

(Low and Common)

B5268

—

Short Probe For Water Level (High)

B5269

—

Reducing Bushing For Water Level

A21391

—

Float Level Assy DI/RO

C4560

—

Float Switch DI/Ro

B5139

Item No.

Steam Generator

Part No.

1

SS Tank For HC-6100/6300

RDHC6000-009-1

—

Thermistor 5 KOHM

With Wire (Aquastat)

RDHC6000-006

—

Tank (HC6100/6300)

D6476

—

Black Knob (6) Used with tank cover

D6478

—

Tank Cover

D6477

—

Tank Gasket

B7872

—

Ionic Bed

B5213

—

Lock and two keys for cabinet

A10789

—

2-3/8" IDx12" EPDM hose cuff

B2851A

—

2" IDx12" EPDM hose cuff

B2851

—

1-1/2" IDx9-5/8" EPDM hose cuff

B2250

—

1" IDx18" EPDM hose cuff

A9620-1

—

Hardware Assembly

B5287

—

Passivated Tank

D2171

25

S-assy Ionic Bed HC-6000

(six required for HC-6100 and HC-6300)

B5213

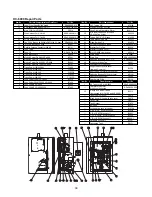

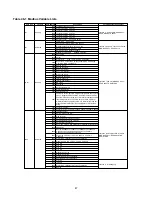

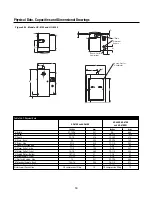

HC-6000 Repair Parts

Item No.

Electrical Compartment and Front Panel

Part No.

31

Label Front Panel With Keypad

RDHC6000-014

16

Emergency Stop Button (2 N.O.)

RDEHU700-065

1

Main PCB For HC-6000

D5814

—

Wire Harness For HC-6100

RDHC6000-013-1

—

Wire Harness For HC-6300

RDHC6000-013-2

32

LCD & Display Board For HC-6000

RDHC6000-012

14

Fan DC24 (Sanyo 9A0924H4D03) With 2 Cover

RDHC6000-004

12

Terminal Block #000 Wire

B5607

11

Definite-Purpose Contactor 50AMP

B2721

6

Fuse 3AMP

A10718

7

Fuse 1A

RDEHU700-073

5

Fuse Block 3AMP

A8649

13

Module Power Din 9KW HC-6000

B5091

13

Module Power Din 15KW HC-6000

B5092

13

Module Power Din 9/15KW HC-6000

B5093

13

Module Power Din 15KW HC-6000

B5151

8

Trans Power 120/240-24V

C1833

8

Trans Power 600-24V

C1833A

8

Trans Power 480-24V

C1833B

8

Trans Power 208-24V

C1833F

8

Trans Power 380-24V

C1833D

3

Fuse Holder 30AMP HC-6000

B4039

3

Fuse Holder 30AMP 250V HC-6000

B7494

4

Fuse 30AMP HC-6000

B4040

4

Fuse 30AMP HC-6000 250V

B7495

38

Item No.

Electrical Compartment and Front Panel

Part No.

Item No.

Water Compartment

Part No.

Item No.

Steam Generator

Part No.

Summary of Contents for HumidiClean HC-6100 Series

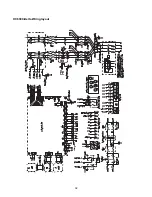

Page 28: ...HC6100 Wye Wiring layout 28...

Page 29: ...HC6100 Delta Wiring layout 29...

Page 30: ...30 HC6100 PAR Single Phase Wiring Layout...

Page 31: ...HC6300 Wye Wiring layout 31...

Page 32: ...HC6300 Delta Wiring layout 32...

Page 33: ...HC6500 Wye Wiring layout 33...

Page 34: ...HC6500 Delta Wiring layout 34...

Page 35: ...35 HC6500 WYE 2 contactors Wiring Layout...

Page 36: ...36 HC6500 Delta 2 contactors Wiring Layout...

Page 37: ...HC6700 Wye Wiring layout 37...