-

22

-

English

Installation

AP030026

C17

C15

4.4

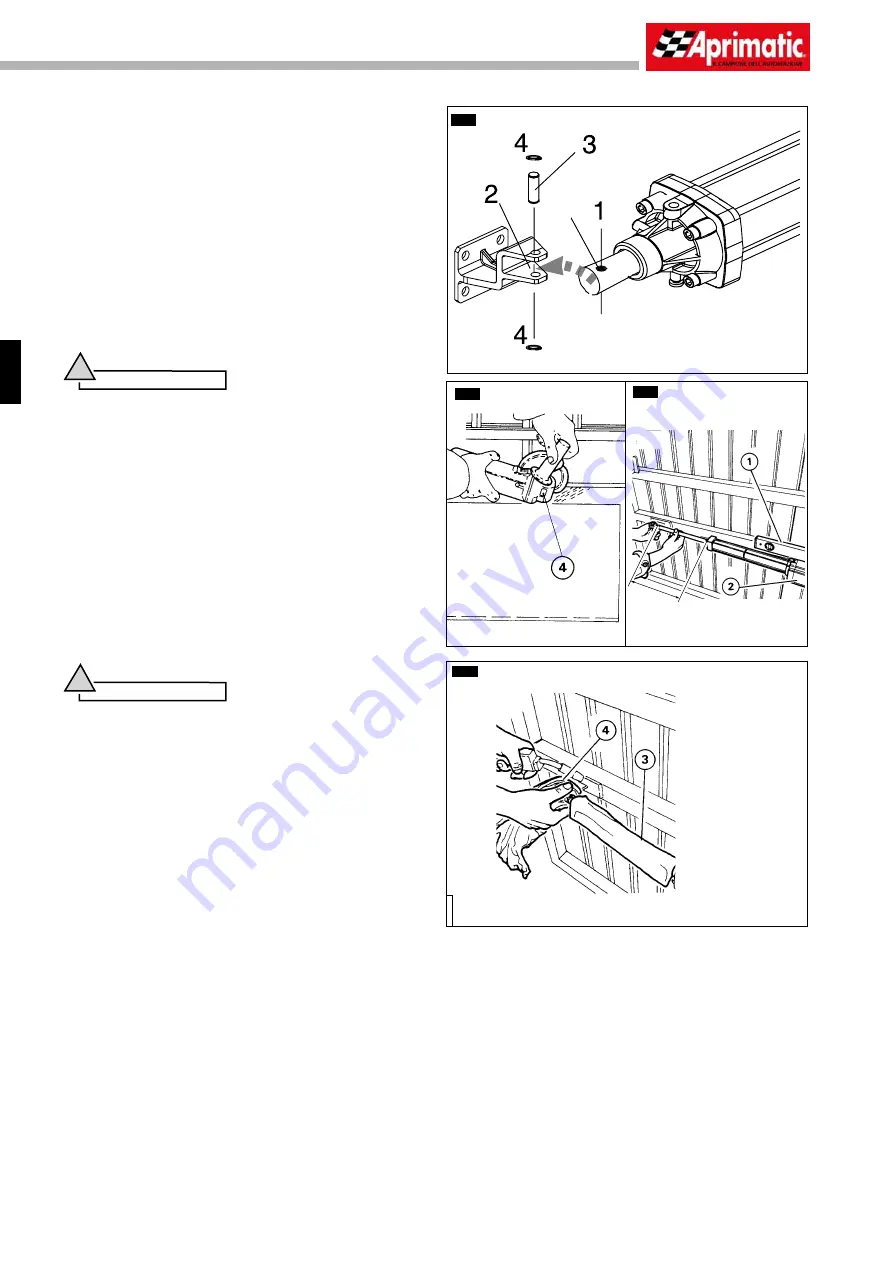

POSITIONING THE FRONT MOUNTING

Smear the hole of the operator rod with grease (

C14

pos.

1

).

Position the end of the rod into the front mounting (

C14

pos.

2

),

then

fi

t the locking pin (

C14

pos.

3

) without tightening the snap

rings (

C14

pos. 4).

If it has been decided to use the maximum useful length of the rod

(distance A+B = useful piston stroke length), proceed as follows:

•

Position the key (

see paragraph 6

) onto the unlock screw and

rotate counter-clockwise to hand-unlock the operator.

•

Slowly extend the rod to end stroke.

•

Withdraw the rod of 5 mm.

•

Protect the rod (

C17

pos.

3

).

•

Perfectly clean the welding zone for the front mounting with a

suitable tool (

C15

pos.

4

); be especially sure to remove any traces

of paint or zinc coating.

Warning

!

• Check the strength of the mounting zone; if necessary, fi t

a strengthening plate of the correct size; the strengthening

plate is especially important with gate leaves made from

thin sheet steel.

• When cleaning the mounting zone for the operator front

mounting, remove the operator and protect it from fl ying

sparks.

Rest a water level (

C16

pos.

1

) on the operator body (

C16

pos.

2

)

and level the operator.

Weld the front mounting of the rod to the gate leaf with two weld-

points, protecting the rod from weld residues with a clean cloth

(

C17

pos.

4

).

Withdraw the rod from the front mounting and remove the operator

itself from the temporary mountings to complete the welding. Protect

the pin (using a clean cloth or adhesive tape) from weld residues,

then clean off the residues with a wire brush.

After cooling, apply a coat of rustproof paint to the welded zone.

Warning

!

• While welding the points on the front mounting with the

electrode, always cover the rod with a clean cloth; a splinter of

molten metal can cause irreparable damage to the machined

surface and make the operator unusable.

• During welding, the operator must be disconnected from

the electricity supply.

C14

300 mm

C16