AQUAKOND AKY

CONDENSING BOILER

31

code HC0048.10GB ed.B-1811

AKY

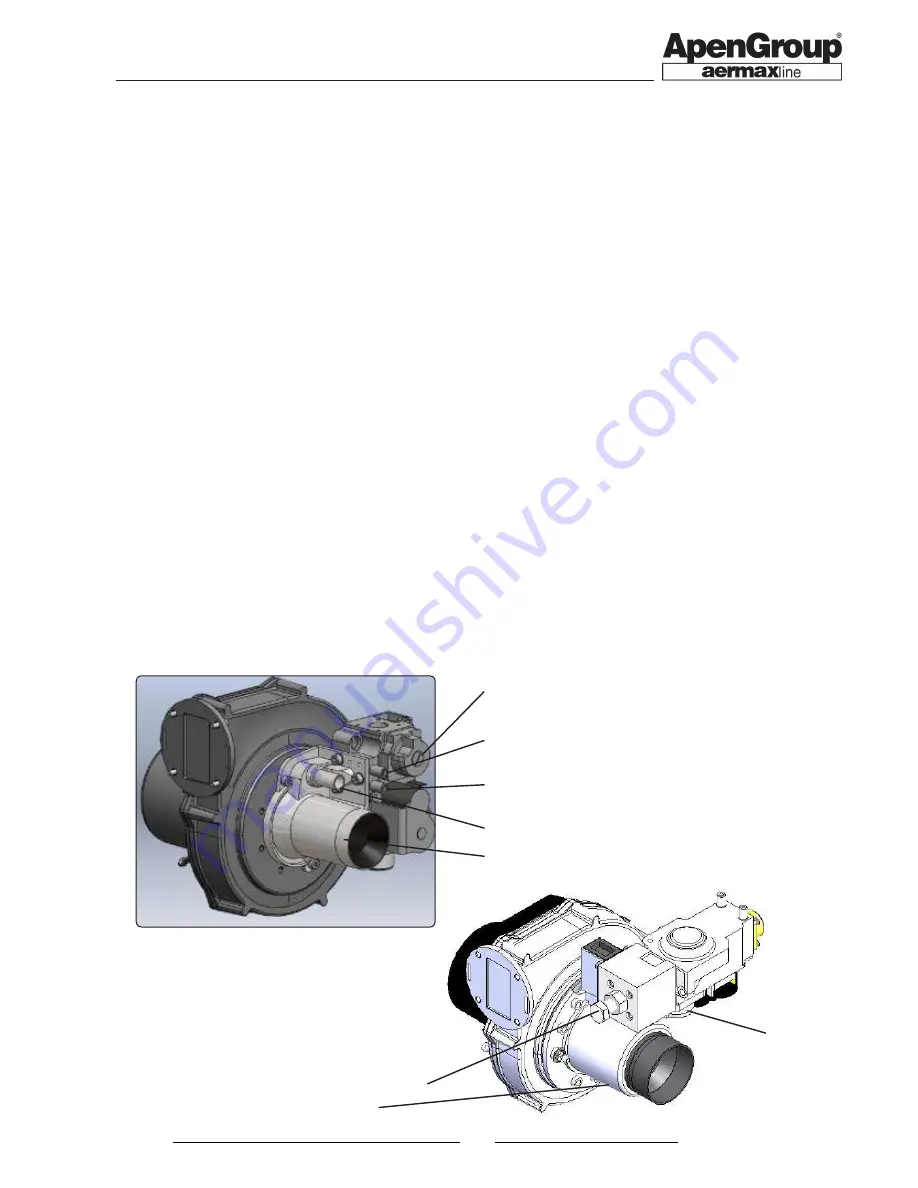

VENTURI

GAS INTAKE PRESSURE

CONNECTOR (IN)

OFFSET ADJUSTMENT

GAS PRESSURE CONNECTOR

ON BURNER (OUT)

PRESSURE CONNECTOR

FOR OFFSET ADJUSTMENT

CO

2

ADJUSTMENT

VENTURI

OFFSET AD-

JUSTMENT

CO

2

ADJUSTMENT

AKY100

AKY032, 034, 050, 070

6.3. First start-up

The boiler is supplied already set up and tested for the gas

specified on the nameplate. Before turning on the boiler, check

the following:

•

make sure the gas being supplied matches the gas for which

the boiler has been set up;

•

check, with the pressure intake "IN" on the gas valve, that

the valve input pressure corresponds to that required for

the type of gas being used;

•

check that the pressure inside the hydraulic circuit is between

1.2 and 1.6 bar;

•

check that electrical connections correspond to those

indicated in this manual or other wiring diagrams enclosed

with the machine;

• check that efficient earthing connections have been completed,

carried out as specified by current safety regulations;

To turn on the boiler, follow the instructions below:

•

provide voltage to the fan heater and, in case of fan heaters

equipped with a speed regulator, set the switch to winter

position and select maximum speed (5);

•

make sure that an ambient thermostat or SmartEASY/WEB

is connected to the boiler.

•

provide voltage to the boiler using the main switch after having

ensured that the three-pin plug is connected to the boiler;

•

when power voltage is provided to the boiler and ID2-IDC2

contact is closed on boiler PCB, the ignition cycle starts;

•

if APEN or Smart EASY/WEB remote control is connected,

refer to the relevant manual for the ignition cycle start

procedure, then continue with the following instruction.

Sometimes, when turned on for the first time, the burner cannot ignite

because there is air in the gas pipe. This will lock out the boiler. You

will need to reset the equipment and repeat the operation until it

ignites (for unlocking operations use the buttons on boiler display).

6.4. Analysis of combustion

Wait until the boiler reaches the maximum output.

Check again that the input pressure in the valve corresponds

to the value required; adjust if necessary.

Perform the combustion analysis to verify that the level of CO

2

corresponds the values contained in the table "GAS SETTINGS".

If the measured value is different, turn the adjustment screw

on the Venturi pipe. Loosening the screw will increase the CO

2

level, screwing it down will decrease the level.

Position the boiler at minimum capacity, check that CO

2

is equal

to or slightly lower than the value detected at maximum capacity

(up to -0.3%). If the values do not match, screw or loosen the

OFFSET screw respectively to increase or decrease the CO

2

level and repeat the procedure.

Flue cleaning function

The boiler can be forced to the maximum or minimum capacity

with the flue cleaning function. This function can be carried

out from the LCD display in REg menu with Hi (maximum heat

output) or Lo (minimum heat output) function.