6

Leak Testing

WARNING

To avoid the risk of fire or explosion, never use oxygen, high pressure air or flammable gasses for leak testing of a

refrigeration system.

Safe Refrigerant Handling

WARNING

To avoid possible explosion, the line from the nitrogen cylinder must include a pressure regulator and a pressure

relief valve. The pressure relief valve must be set to open at no more than 150 psig.

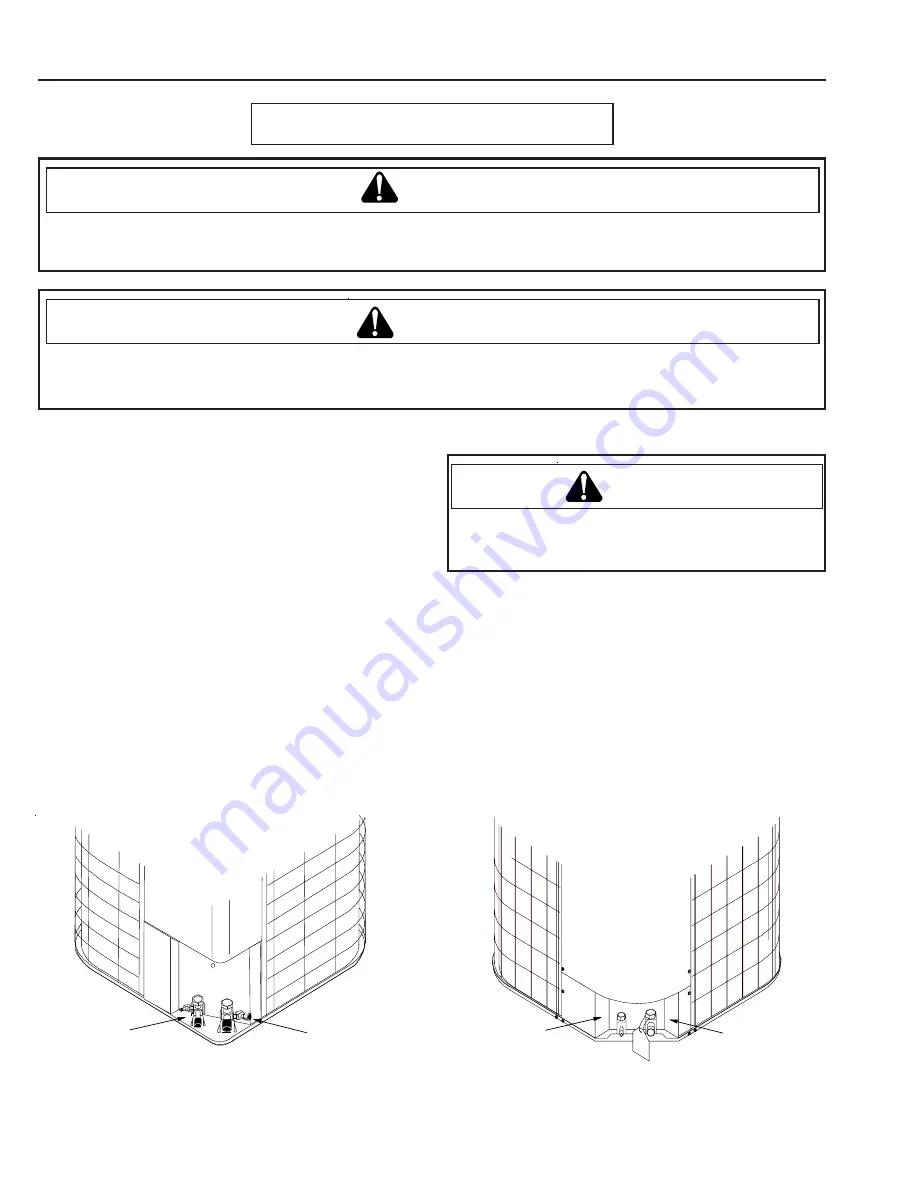

1. Be sure both hand valves on the gauge manifold are

closed relative to the center port (i.e., turned in all

the way.) Attach this gauge manifold to the service

valves on the unit (see Figure 2). Do not open the

unit service valves. Do not use refrigerant from the

unit for leak testing - it has been precisely measured

at the factory for optimum performance.

2. Connect a cylinder of dry nitrogen to the center port

on the gauge manifold.

3. Open the hand valve a minimal amount on the line

coming from the nitrogen cylinder.

4. Open the high pressure valve on the gauge mani-

fold. Pressurize the refrigerant lines and the indoor

coil to 150 psig (1034 kPA). To reach 150 psig, you

may need to further open the hand valve on the ni-

trogen cylinder.

WARNING

To avoid possible explosion or equipment damage,

do not exceed 150 psig when pressure testing.

After you reach 150 psig, close the valve on the nitrogen

cylinder. Disconnect it from the gauge manifold. If you plan

to use an electronic leak detector, add a trace of R-22 to the

system (if permitted by current EPA regulations).

5. Place a chloride-free soap solution on all connections

and joints. If you see bubbles, you have a leak. Mark

these locations.

6. Use the gauge manifold to carefully release the nitro-

gen from the system. If leaks were found, repair them.

After repair, repeat the above pressure test. If no leaks

exist, proceed to system evacuation.

Figure 2

LIQUID LINE

SERVICE VALVE

VAPOR LINE

SERVICE VALVE

LIQUID LINE

SERVICE VALVE

VAPOR LINE

SERVICE VALVE