Instruction manual 91/104 V9.2

Installation

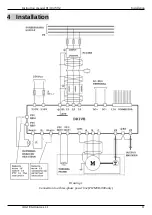

4.2 Motor wiring

Only use shielded cable with 3 cond earth for powering the motor and twisted shielded cable in pairs for the transducer ( AL

-

TER model

CAV16PSCH-SP1

).

The section of the conductors of power cables is shown in drawing 2 on page 7.

Connect the shields of the power and signal cables to the case of the drive and motor.

The connection of the shield to the case shall be as short as possible (maximum length 100 mm). The uncovered part of the cable shall

not exceed 50 mm.

It is recommended to use shielded cables without joints. If this is impossible, use:

•

For signals: shielded connectors that do not interrupt the shield

•

For power: shielded connectors or terminal blocks.

If a terminal block is used, the uncovered (unshielded) part of the cable must be minimised and the shields of the two cables must be

connected to a (non-insulated) ground terminal.

Using the following formula, calculate the value of the “electric time constant " of the motor; If the result is less than 10msec, an in-

ductance between the motor and the drive shall be mounted. In case of doubt or for further information, please contact the ALTER

Technical Office.

T

e

=

L

mot

R

mot

T

e

=

Electric time constant [msec].

L

mot

= Inductance of the motor (see motor technical specifications) [mH].

R

mot

= Resistance of the motor (see technical specifications of the motor).

For the sizing of the components drawn in Drawing 1 on page 11 and in Drawing 2 on page 12, see 2 on page 7.

Connect the thermal probe as indicated in Drawing 1 on page 11 or Drawing 2 on page 12 only if the signal is not available on the

transducer connector.

4.3 Power connections

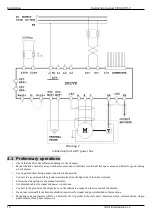

To identify the location of the connectors on the drive, see Drawing 29 on page 85 and Drawing Drawing 30 on page 86.

4.3.1 Three-phase or single-phase network (only for PWM3D-000)

The three-phase power supply network shall be connected to the L1

,

L2

,

L3 terminals

available

on the X1 connector in the case of a

size 1 drive or on a screw terminal in the case of a drive of size 2.

Only for

drives in size 1

it is possible to supply them with

single-phase

voltage: In this case, use only the

L1

and

L2

terminals.

NOTE:

The contacts of the contactor mounted on the power supply line (as indicated in Drawing 1 on page 11) can be closed only

if the DOK output is active at +24V; in the event that the DOK output go to 0V (in case of alarm for example) the switch must be

opened immediately.

The diagram next to it illustrates the correct connection of the

contactor coil control that dissects the power supply to the drive.

The digital output “DOK” of the drive controls the coil of a

24Vcc relay (RL1) and the same signal goes to the PLC or CNC

to signal if the drive goes to FAULT.

The auxiliary contact of the RL1 relay is serialised to the coil of

the power contactor (K1) which is controlled by the CNC or PLC

whenever it wishes.

In the case that the drive goes into alarm or in case of lack of

power to the auxiliary services, thus making the contactor off and

the power supply on the L1, L2, L3 is removed even if the CNC

tries to drive the K1 contactor.

This ensures the correct management logic of the contactor.

4.3.2 Motor

The motor must be connected to terminals

A, B, C.

In the case of a drive size 1 this connection is on the X2 connector; instead, with a

drive size 2 you have to use the special screw terminals.

Alter Elettronica s.r.l.

13

Drawing 3