© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

1300003 (EN)

12

Required Materials

IMPORTANT: Keep finisher area clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

Location Requirements

IMPORTANT: Transport finisher on skid until

near area of desired installation. Reasonable care

should be taken during installation.

Finisher is shipped with manual crank located on tray.

Be certain to keep manual crank near machine for easy

access.

NOTE: With its trays removed, the finisher will fit

through a 32 inch (813 mm) wide door.

.

To assure compliance, consult and adhere to building

code requirements and comply with the following:

•

The finisher must be installed in a very well

ventilated room (especially when using gas

heating) with correct lighting and an ambient

temperature in the range from 32°F (0

o

C) to

+ 104°F (40

o

C).

•

Leveling should be carried out correctly on a

hard and stable floor surface, capable of

supporting the weight of the finisher. The floor

must at least be able to support 150 lbs./ft

2

(732 kg/m

2

) for the installation of the finisher.

•

The finisher MUST NOT be installed or stored in

an area where it will be exposed to water and/or

weather.

IMPORTANT: DO NOT block the airflow at the

rear of the finisher with laundry or other articles.

Doing so would prevent adequate air supply to the

combustion chamber of the finisher.

Sufficient space must be left around the finisher to

allow for its correct functioning.

•

Allow at least 4 inches (102 mm) in the back to

allow for ventilation.

•

Allow 32 inches (813 mm) on each side for

upkeep and maintenance.

•

Allow sufficient space in front so that the

operator can work efficiently and safely.

Lifting the Finisher

The finisher should be moved with a forklift as close

as possible to the area where it will be installed. Use a

forklift of sufficient capacity to lift the packaged unit

according to the following procedures.

IMPORTANT: DO NOT lift finisher with slings.

1. Position the forklift arms beneath the center of

the unit (NOT toward either end) to lift the

finisher at its center of gravity.

IMPORTANT: Lifting the finisher from either side

could cause misalignment and/or damage to the

finisher.

2. Adjust the forklift arms to their maximum length

and width and insert them all the way under the

center of the skid. Refer to

Figure 3

.

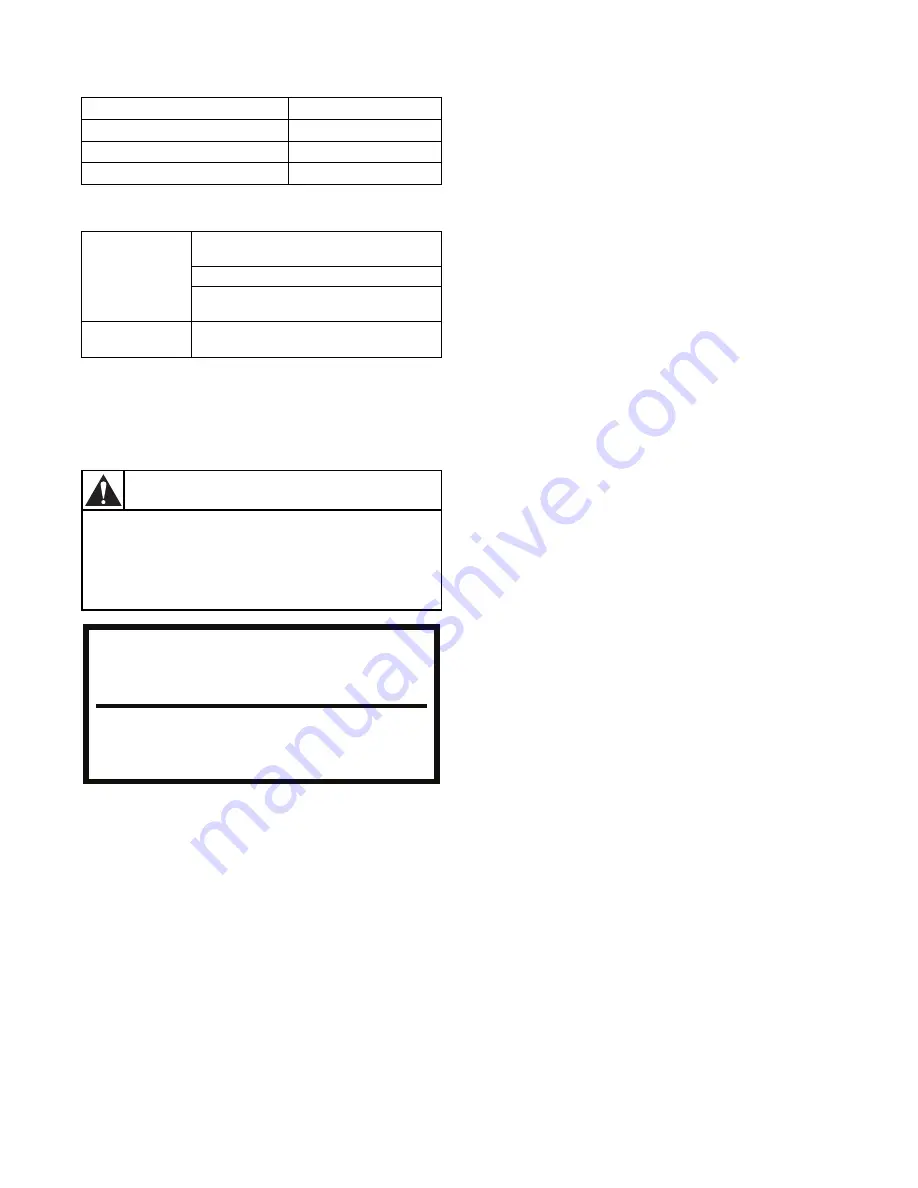

Model

Weight

UD13F063

1320 lbs. (599 kg)

UD13F078 and UD13F079

1474 lbs. (669 kg)

UD13F126

2094 lbs. (950 kg)

All Models

One fused disconnect switch or branch

circuit breaker (obtain locally)

Pry bar

Three 3.5 inch (89 mm) to

4 inch (102 mm) rollers or pipes

Gas Models

One gas shut-off valve for gas service line

to each finisher (obtain locally)

To prevent fire, explosion, or personal

injury, this finisher may only be installed,

adjusted, and started up by a team of

qualified technicians.

W543

WARNING

This machine must be installed in compliance with all local regulations and used

only in a room with adequate ventilation air. Important, read manuals before

installing, operating, servicing or cleaning machine.

Min clearance from both combustible and noncombustible

Construction; 4" from back, 20" from side.

Cet appareil doit être installé conformemént aux réglementations en vigueur et

utilisé seulement dans un endroit bien aéré.

Lire les notices avant d'installer, utiliser, entretenir ou nettoyer la machine.

Espace mini entre machine et matière combustible ou non- combustible:

arrière: 4", côté :20"

FWF141N

FWF141N