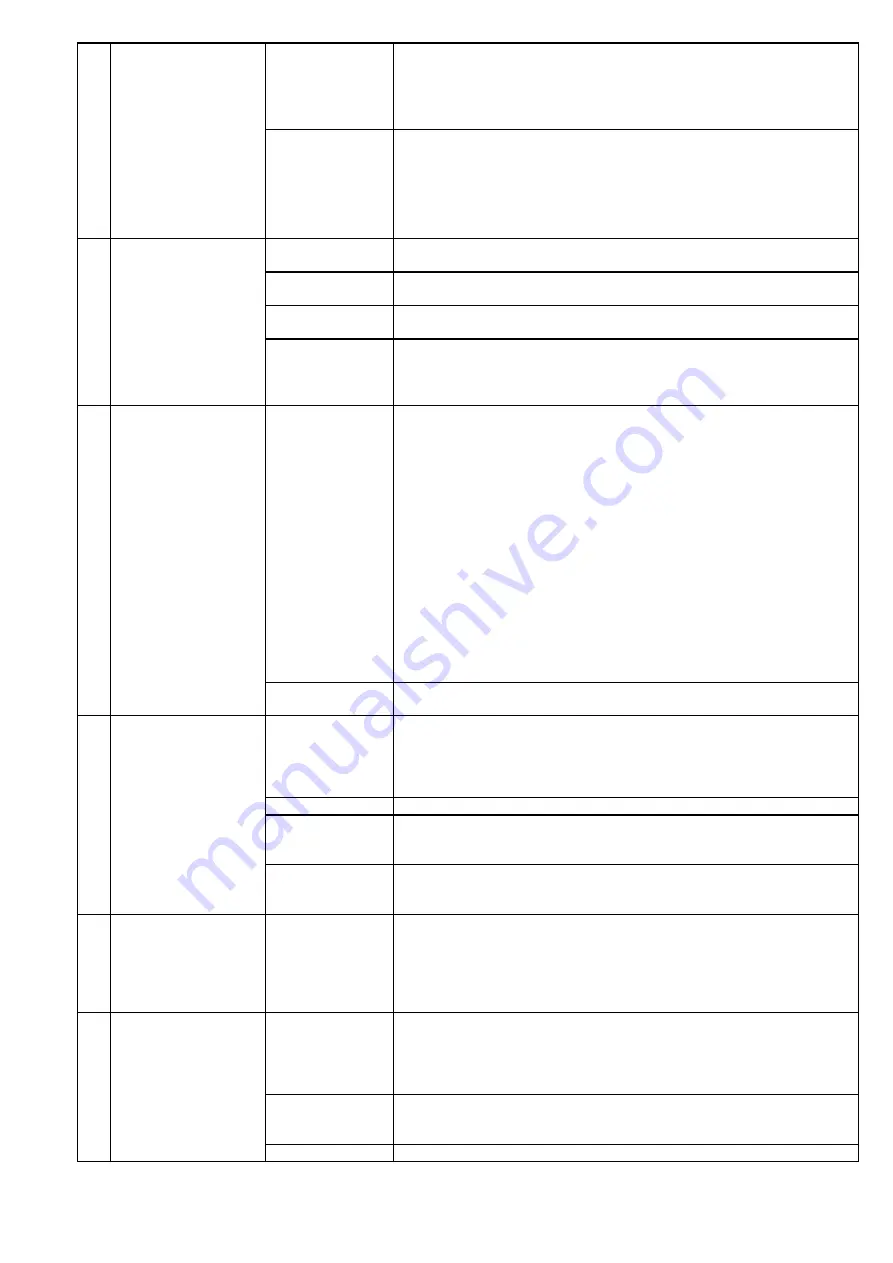

13

5

The safety valve drains

water from the

installation, and the

pressure is less than 3

(2,5) bar

The pressure in the

installation is more

than 3 (2,5) bar and

the safety valve does

not drain water from

the installation

Safety valve

failure

Replace safety valve

Safety valve

failure

Replace safety valve

6

Sudden water

temperate increase in

the installation

Air in the

installation

Perform radiator venting

Closed valves

towards radiators

Open all valves in the heating system and provide normal water

circulation in the installation

Circulation pump

failure

The circulation pump should be repaired or replace it thereby allowing

operation of the heating system

Electrical power

loss

You should open all valves that reduced the heating system. This mostly

refers to the “by-pass” valve.

Stop or reduce stoking with strong control so that the water temperature

in the system would not exceed 90

C until electricity arrives.

7

Sudden pressure

increase in the

installation while

water temperature

increase

Decreased

pressure in the

expansion vessel

or completely

empty. Remove

the cover or the

vessel valve cap

and release some

air through the

valve. If the

membrane is

destroyed, water

shall leak from

the valve, and if it

is only half-

empty, only air

will come out

If water is leaking from the valve, replace the expansion vessel.

If only air comes out from the valve, remove the installation vessel and

pump it. The pressure in the vessel must be equal to or greater than

height difference of the highest and lowest installation point. Example:

For height difference of 5m. the pressure is Pmin.

0,5 bar.

Air in the

installation

Perform venting of the installation

8

The circulation pump

does not switch on or

blow a fuse

No power on the

electrical

connection.

Loose

connectors.

Check and tighten the screws at the connection spots. Check and if

necessary, replace the fuses, eliminate the malfunction of the motor or

installation connection

Capacitor failure

Replace the capacitor

Rotor blockage

Before the start of each heating, examine the easy rotor turning. Hot water

deposition may lead to rotor blockage. Turn around the motor shaft with a

wrench until free turning of the rotor is enabled.

The pump is

blocked due to

sediment

Disassemble and clean the pump.

9

The thermometer or

manometer does not

show the amount of

temperature or water

pressure in the

installation

Thermometer or

manometer failure

Replace the thermometer or manometer

10

Noise (sounds) from

the eating system

Defective pump.

Great clearance

between the rotor

shaft and

bushings

Reduce pump speed. Replace the pump envelopes or the entire pump

The pump is

functioning at too

high speed

Select low speed.

Air in installation

Release air from the heating system