INSTRUCTIONS FOR USE

AGP 300 – 600 PRO

Rev.02/2019

30

7.8

Strainer and packaging cleaner

This accessory ensures easier handling of spraying agents. The strainer contains a special nozzle,

which directs the liquid from the nozzle towards the bottom part of the strainer to flush out the

spraying agent (powder) added through the strainer. It also enables packaging cleaning. The

cleaner is attached to the one-way diverter valve of the pressure regulator or directional control

valve by means of a hose connection between the valve and the mixing nozzle.

When the diverter valve for packaging and strainer cleaning is opened, it is necessary to adjust the

pressure (5-10 bar). This activates the strainer rinsing function, which is useful for rinsing powder-

based spraying agents (1). If liquid spraying agents are used, the protective film under the

packaging lid can be penetrated with the pointy top of the rinsing nozzle. (2). When the entire

content of the packaging (bottle) is emptied, push the neck of the bottle or plastic container over

the nozzle and to the limiter (3). This activates the nozzle, which thoroughly washes the inside of

the packaging. When the packaging is removed, the flow is closed.

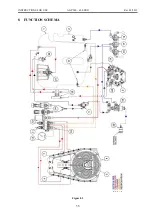

Figure 7.5

7.9

Blower

There are two blowers available that differ in the height of the blower and the number of nozzles:

•

1700: blower with a height of 1700 mm and 18 nozzles (option of individual closing and

adjustment of height and direction), with 2 or 4 sections. This model is primarily used in

fruit growing, but it can also be used for other plantations and crops.

•

1070: blower with a height of 1070 mm and 14 nozzles (option of individual closing and

adjustment of height and direction), 2 or 4 sections. This model is primarily used in

viticulture, but it can also be used for other plantations and crops.

WARNING: The nozzle shape shown in the figure is symbolic and may not

reflect the actual state of equipment on the mist blower!