BE-BX42S / BE-WC62G USER MANUAL

25

MOUNTING & UNHOOKING TRACTOR (CONT.)

BE-BX42S / BE-WC62G

Leveling Adjustments

1. Slowly raise the machine through its working range

to make sure telescoping portion of the PTO shaft

doesn't bottom out.

2. Level the machine front & rear and side to side using

the jack screw on the right arm and the turnbuckle on

the top link.

NOTE

- The chipper should always be level on the

ground in its working position.

3. To unhook from the tractor, reverse the above

procedure. Always perk the machine in a dry level area.

If vandalism is a problem, remove the PTO driveline

and store in a secure place.

Fig. 19

Connect the hydraulics

1. Use a clean rag or paper towel to clean the dirt

from couplers on the hose ends and the tractor.

2. Connect the hoses to the tractor couplers.

Be sure the couplers are securely seated.

3. Route and secure the hoses along the hitch

with clips, tape or plastic ties to prevent

binding and pinching. Be sure to provide

slack for turning.

NOTE

- Always connect to the hydraulic circuit

with a detent.

Fig. 18

WARNING

HIGH PRESSURE FLUID HAZARD

To prevent serious injury or death from

high pressure fluid:

• relieve pressure on system before

repairing or adjusting.

• Wear proper hand and eye protection

when searching for leaks. Use wood

or cardboard instead of hands.

• Keep all components in good repair.

Z9400

Leveling Adjustments

1. Slowly raise the machine through its working

range to make sure telescoping portion of the

PTO shaft doesn’t bottom out.

2. Level the machine front & rear and side to side

using the jack screw on the right arm and the

turnbuckle on the top link.

NOTE

- The chipper should always be level on

the ground in its working position.

3. To unhook from the tractor, reverse the above

procedure. Always perk the machine in a dry

level area.

If vandalism is a problem, remove the PTO

driveline and store in a secure place.

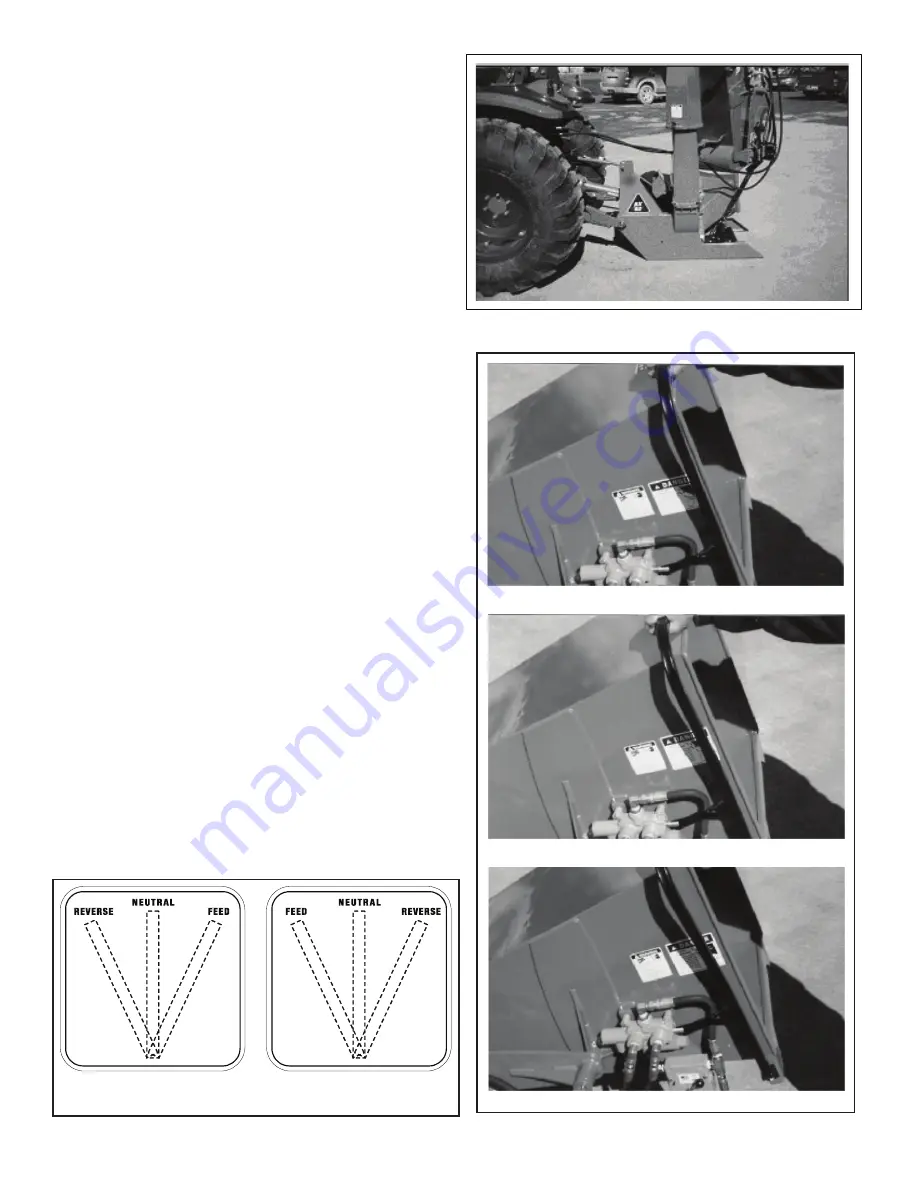

CONTROLS

All controls are conveniently positioned next to

where the operator would stand when feeding the

machine to provide easy operation. Review this

section to familiarize yourself with the location and

function of each control before starting.

Hydraulic Feed Control Lever:

This lever is positioned to extend around the feed

hopper and provides access from all sides. It is only

available when the chipper is equipped with the

optional hydraulic feed hopper.

Pull the control all the way out to engage the

feeding system. Push it in slightly to the first detent

to stop the feeding system. Push the control all the

way in to reverse the feeding system.

NOTE

- Use the typical flow divider next to the

control valve to set the feeding spread.

CONTROLS

BE-BX42S / BE-WC62G

Z940

Z940

Z940

Z940 4444

Z940

Z940

Z940

Z940

Feeding

Neutral/Stop

Reversing

Left Side

Right Side

Control Schematic

Fig. 20

All controls are conveniently positioned next to where

the operator would stand when feeding the machine

to provide easy operation. Review this section to

familiarize yourself with the location and function

of each control before starting.

Hydraulic Feed Control Lever:

This lever is positioned to extend around the feed hopper

and provides access from all sides. It is only available

when the chipper is equipped with the optional

hydraulic feed hopper.

Pull the control all the way out to engage the feeding

system. Push it in slightly to the first detent to stop

the feeding system. Push the control all the way in to

reverse the feeding system.

NOTE

- Use the typical flow divider next to the control

valve to set the feeding spread.

CONTROLS

BE-BX42S / BE-WC62G

Z940

Z940

Z940

Z940 4444

Z940

Z940

Z940

Z940

Feeding

Neutral/Stop

Reversing

Left Side

Right Side

Control Schematic

Fig. 20

All controls are conveniently positioned next to where

the operator would stand when feeding the machine

to provide easy operation. Review this section to

familiarize yourself with the location and function

of each control before starting.

Hydraulic Feed Control Lever:

This lever is positioned to extend around the feed hopper

and provides access from all sides. It is only available

when the chipper is equipped with the optional

hydraulic feed hopper.

Pull the control all the way out to engage the feeding

system. Push it in slightly to the first detent to stop

the feeding system. Push the control all the way in to

reverse the feeding system.

NOTE

- Use the typical flow divider next to the control

valve to set the feeding spread.