Ag Leader Technology

DirectCommand Installation

Raven Accu-Flow ISO Kit

Page 14 of 15

February 2015

PN: 2006375 Rev. B

Setting Up

the Display

1. Refer to the Quick Reference Guide, PN: 2006010-ENG, for further

instructions on setting up the Display.

2. The following table describes each of the settings required to create a

configuration. The table on the following page is recommended default

settings based on which control valve is used.

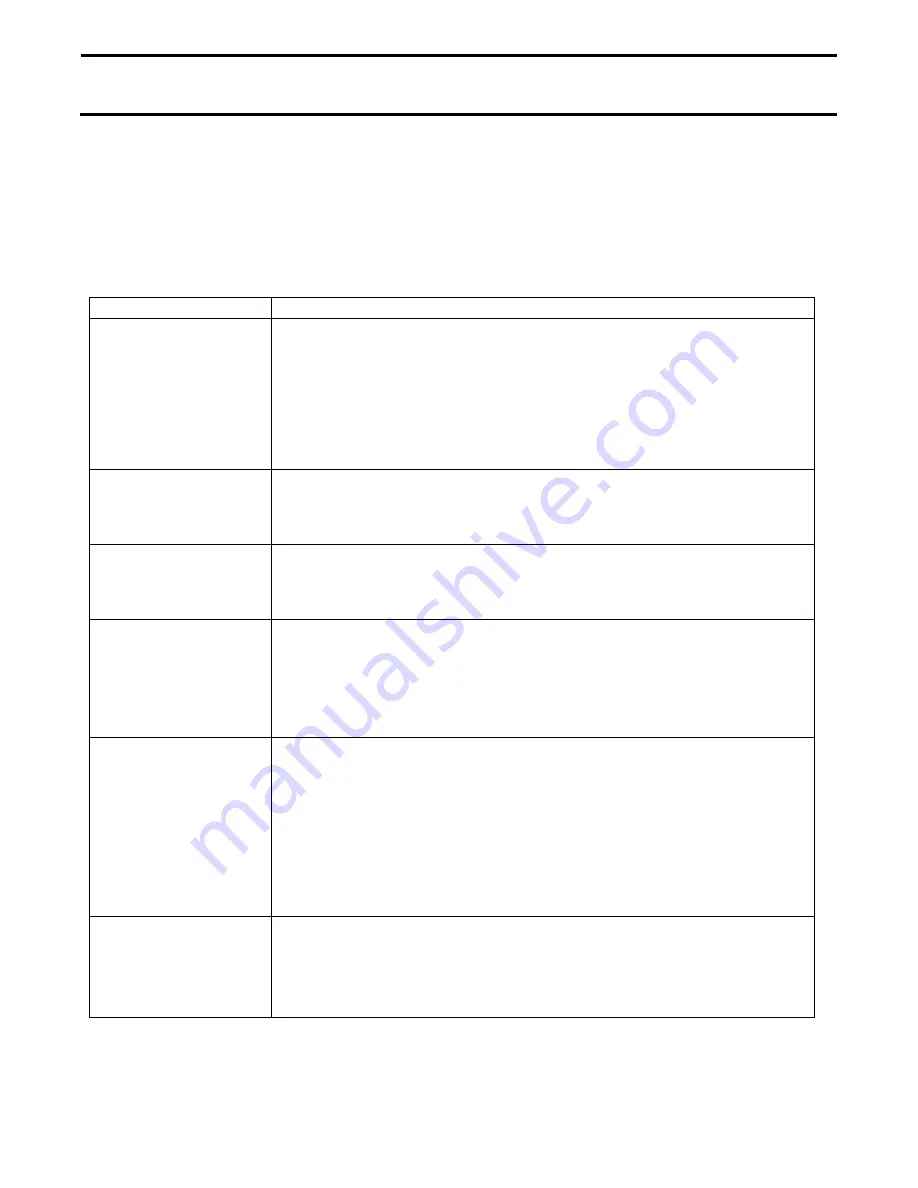

Setting Name

Description

Control Valve

Configuration

Inline Servo:

Rate control is achieved through actuating a control

valve in the solution hose that goes to the booms. When the valve

opens flow increases and when the valve closes, flow decreases.

Bypass Servo

: Rate control is achieved through actuating a control

valve in the return line to the solution tank. When the valve opens, the

flow decreases and when the valve closes the flow increases.

Valve Response 1

Determines the speed of the servo valve when product control error

exceeds the

Response Threshold

setting. Decreasing the value will

cause the servo valve to run slower

Valve Response 2

Determines the speed of the servo valve when product control error is

less than the

Response Threshold

setting. Decreasing the value will

cause the servo valve to run slower.

Allowable Error

Determines the percent of error that is allowed prior to the product

control system making any flow rate corrections.2 % – 3 % is the normal

dead band setting range. Too low of a setting will cause the control

system to continually hunt for the target application rate. Too high of a

setting will cause excessive application error.

Response

Threshold

Determines where the control system switches between using

Valve

response 1 and Valve response 2 speed settings. Decreasing this value

will have the overall effect of speeding up servo valve response.

Increasing this value will have the overall effect of slowing down servo

valve response.

NOTE: Leaving all other valve control settings at the default

value and making a small adjustment to this setting is usually

all that is required to fine-tune the control system.

Flow Meter Cal

This is the number pulses per 10 gallons of product flow thru the Raven

flow meter. The Ag Leader Display requires pulses per gallon for

calibration. To calculate the appropriate values divide the Raven

calibration number by 10 before entering into the Ag Leader Display.