Installation, assembly and setting

Assembly instructions EN

DG 16

Edition 07/2020

Rev. 3.0

31–50

6.2 Preparation - Manufacture of the gripper fingers

The fingers needed for gripping the parts must be designed and manufactured.

For most applications the gripper fingers’ design can be symmetrical. The

gripper fingers can be attached to the gripping jaw or the rotary head.

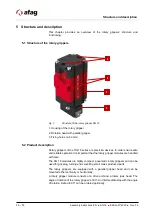

Fig. 11

Example rotary gripper DG 16

The maximum length of the gripper fingers is 30 mm!

Observe the maximum permissible gripper finger loads in

Chapter 3.1.6

„Technical Data“ in this manual.

Attachment to the rotary head:

Fig. 12

Example rotary gripper DG 16

For the 90° end stop (fixed stop) of the DG 16 the customer can mount his

own components such as hold-down devices.

These components are fixed to the centering holes/ fixing holes on both sides

of the rotary head.

Attachment to the rotary head (1)

1