Page 30

ES/ESH-LT209_10152019

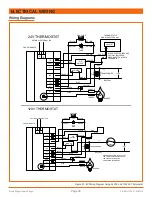

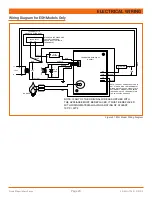

Single Stage Unitary Range

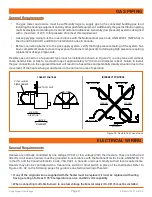

Starting Sequence of Operation

•

Turn the thermostat up. When the thermostat calls for heat, the blower motor will energize.

•

When the motor approaches nominal running RPM, the air-proving switch closes and activates the ignition

module.

•

The ignition module, after a pre-purge period of approximately 30 seconds, energizes the igniter. Additionally,

the gas valve is energized for this ignition trial period of 15 seconds.

•

If a flame is detected, the ignition sensing rod "reads" a rectification signal and the gas valve remains open.

The sparking stops when the flame signal is established.

•

If no flame is detected, the gas valve closes and a 30 sec inter-purge period begins. After the interpurge,

the module repeats the trial for ignition period. If flame is still not established, a third and final inter-purge

followed by a final ignition trial cycle begins. After three trials, the module will lockout for a period of

approximately 1 hour or until reset. (Reset is accomplished by removing power from the module for at least

5 seconds.) After this 1-hour period, the module re-attempts the full ignition sequence.

•

When using a 24V thermostat and the heat requirement has been met and the thermostat opens, the

burner shuts off but the fan continues to run for approximately 30 seconds. This is referred to as a post

purge. This allows the products of combustion to be removed from the heat exchanger to avoid nuisance

condensation and increase heat exchanger life.

•

When using a line voltage thermostat and the heat requirement has been met and the thermostat opens,

the burner and fan shut off with no post purge.

Maintenance

For best performance, certain minimal maintenance procedures should be performed before each heating

season:

•

Before performing any services or maintenance, shut off gas and electrical supply to heater.

•

Check condition of forced air blower scroll and motor. Dirt and dust may be blown or vacuumed from the

blower.

•

Check condition of burner. Remove any foreign objects or debris from inside the burner box or burner cup.

•

Inspect the igniter. Replace igniter if there is excessive wear or erosion, breakage or other defects.

•

Be sure the burner observation window is clean and free of cracks or holes. Clean or replace as necessary.

•

Check the flue pipe for soot or dirt and reattach to the heater after cleaning as necessary.

•

The reflector sections may be cleaned by wiping with a damp cloth.

•

A service agency qualified to adjust and repair infrared heaters should be engaged for service other than

routine maintenance.

•

Be sure vent terminal and fresh air inlet are free from obstructions. If either pipe is restricted, the safety air

switch will not operate properly, and the heater could fail to operate.

•

Check the inside of the heat exchanger tube visually with a flashlight. If carbon or scale are present, scrape

or otherwise remove deposits (a wire brush works well)

BURNER OPERATION

Summary of Contents for ES/ESH Series

Page 2: ......