Installation Manual I Operation

19

MP4010-1903

4.7.3 Weekly Cleaning - Connected

1. Close the drain valve and add 1 cup (8 ounces or 0.24

liters) of white vinegar to the cooking compartment.

Start the steamer in the Cook Mode. The cooking

compartment will automatically fill with water. After 15

minutes, turn the steamer off and allow the steamer

to cool to 140°F or lower. Then open the drain valve

and allow the water in the cooking chamber to drain

completely.

2. To rinse close the drain valve and start the steamer

in the Cook Mode. The cooking compartment will

automatically fill with water. After 15 minutes turn the

steamer off and allow it to cool to 140°F or lower. Open

the drain valve and let it drain completely.

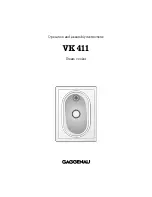

3. Remove the cooking chamber components in this

order: pan rails, steam distributor, steam collector,

overfill sensor, power plate and dry them with a

clean dry cloth.

4. Clean the water sensors with a non-metallic cleaning pad

to remove any scale of debris left over after the cleaning

process. Wipe with a clean dry cloth.

5. Wipe the inside of the cooking chamber with a clean

dry cloth make sure to dry around the corners and seams

of the cooking chamber (FIGURE 19).

6. Install the overfill sensor and the steam collector, resting

the steam distributor on top of the steam collector align

the 4 retaining fasteners and hand tighten, then install the

pan rails and the condensate tray. Leave the door open

overnight.

(NOTE: The steamer will not operate without the overfill

sensor.)

4.7.4 Weekly Cleaning - Connection-less

1. Close the drain valve and add 1 cup (8 ounces or

0.24 liters) of white vinegar to the cooking chamber

and fill with approximately 2½ Gallons of tap water, shut

the door and turn the steamer on.

2. After 15 minutes, turn the steamer off and allow the

steamer to cool. Open the drain valve and allow the

cooking chamber to drain completely.

3. To rinse close the drain valve, fill with approximately

2½ Gallons tap water, close the door and start the

steamer Cook Mode. Let it run for 15 minutes, turn the

steamer off and allow the steamer to cool. Open the

drain valve and allow the cooking chamber to drain

completely.

4. Remove the pan racks, steam collector and steam

distributor for cleaning. Clean the water sensors

with a non-metallic cleaning pad. Wipe the inside of

the cooking chamber, water sensors, pan rails, steam

distributor and steam collector (FIGURE 19).

5. Install the steam collector first, resting the steam

distributor on top of the collector align the ( 4)

retaining fasteners and hand tighten and then install

the pan rails. Leave door open overnight.

PAN RACKS

OVER FILL SENSOR FLOAT

PAN RACKS

STEAM

DISTRIBUTOR

LEFT WALL OF COOKING

CHAMBER

LOW WATER

SENSOR

UPPER LEVEL

WATER SENSOR

DRAIN

STEAM

COLLECTOR

FIGURE 20

Summary of Contents for EVOLUTION Series

Page 26: ......