Installation Manual I Installation

12

MP4010-1903

3.10 Ventilation

DO NOT connect Drain or Vent lines on multiple

appliances. Each appliance should have its own dedicated

drain and vent.

The steam vent is provided with a 45 ° elbow. The steam

vent must not be obstructed. An obstruction will prevent

correct operation of the steamer.

Applicable federal, state and/or local plumbing codes will

dictate when and if a hood is required.

3.10.1 Steam Vent Extension

When adding anything to the vent on the Evolution steamer,

care must be taken to prevent doing anything that puts a back

pressure on the steamer. Back pressure on the steamer may

interfere with the pressure switch that controls the heaters.

When the pressure switch senses pressure in the steamer

that is 0.5” of water column or more, it turns the heaters off.

Therefore, anything on the vent putting a pressure of just 0.5”

water column on the steamer turns the heaters off and prevents

them from coming on again until the pressure is relieved.

Intermittent operation of the steamer can often be traced to

restrictions, low spots or a plugged condensate drain in the vent

fitting assembly.

To prevent putting a back pressure on the steamer, vent piping

should have no restrictions and no low spots where water can

accumulate. Ventilation piping can be directed upwards toward

hoods or downward towards floor drains. Slightly different

approaches are required for each application.

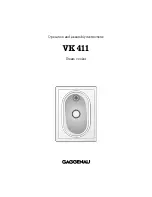

FIGURE 12

18” - 36” Long = 3/4” Diam-

eter brass pipe (both ends

threaded)

45 ° Elbow = 3/4” Diameter

brass pipe (both ends female)

6” - 10” Long - 3/4” Diameter

brass pipe (both ends threaded

male)

Extension Sloping Upward (FIGURE 12)

1. Use nominal ¾” copper, brass or stainless steel to prevent

flow restrictions. Larger inside diameter (ID) can be used also

2. Pipe should slope upward a 1/4” per foot from the steamer

vent toward a vent hood to allow water condensing in it to

run back to the steamer and down the drain line. Minimum

recommended slope is ¼” per foot of hose length.

3. Use rigid pipe rather than flexible tubing or hose to prevent

dips or sags in the pipe that may collect water. A puddle

of water in the piping just ½” deep will cause the steamer

to malfunction. Recommended pipe materials are rigid ¾”

copper tubing (7/8” OD) or brass/ 18-8 stainless steel pipe

(3/4 NPT or larger). Pipe hangers or pipe supports should be

used every six feet to prevent long runs from sagging.

4. A pipe union should be installed next to the steamer to

permit the vent to be easily disconnected. This allows the

steamer to be easily moved for servicing.

5. Total length of extended vent piping should not exceed 15

feet.

Summary of Contents for EVOLUTION Series

Page 26: ......