19

ADJUSTMENTS (Continued)

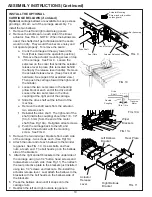

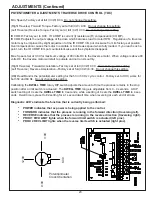

FIG. 25

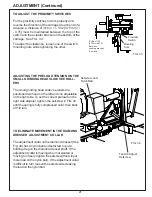

TO REPLACE THE CARRIAGE LINEAR BEARINGS

7.

Attach the three linear bearing pillow blocks and wiper brack-

ets loosely to the bottom of the carriage, with their tension

adjustment screws (FIG. 23) facing outward.

8. Clean the carriage rails.

NOTE: The two rails are interchangeable and are also

reversible (end-for-end).

9. Insert a rail through the rear two pillow blocks, and align

the rear pillow blocks to each other with a straight edge

laid along their sides. See FIG. 25. When aligned, tighten

the four socket-head screws which hold each rear pillow

block. Slide the other carriage shaft through the front

bearing, but do not tighten the socket head screws.

10. Lift the complete carriage assembly back onto the

Grinder main base, and secure the rear carriage rail

to its V-groove bosses with the six bolts.

11. With the front rail resting in the V-groove bosses and the

carriage approximately centered on the machine, tighten

the two outside socket-head screws which secure the front

pillow block. Lift the front of the carriage, and tighten the

two inside pillow-block screws. Secure the front carriage

rail to its V-groove bosses with the six bolts.

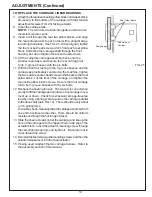

12. Recheck the bearing tension. The tension is correct when

you try to lift the carriage and can feel no free carriage move-

ment up or down. Check for excessive carriage-traverse

load by using a spring scale to pull on the carriage parallel

to the drive shaft (as in FIG. 19). There should be only about

a 3 lb. pulling force.

To double-check, manually slide the carriage assembly from

one end of its travel to the other. There should be uniform

resistance through the full range of travel.

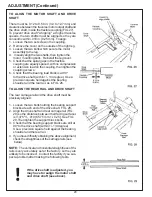

13. Slide the linear actuator under the carriage, and line up the

hole in the carriage with the tapped hole in the top of the

actuator block. Insert the actuator mounting screw through

the self-aligning bearing, and tighten it. Be careful not to

cross-thread the screw.

14. Reinstall the feed screw guide mounting screws and then the

actuator release lever into the linear actuator.

15. If being used, reattach the two carriage bellows. Refer to

the assembly section of this manual.

Rear Pillow Blocks

Underside of

Carriage

Straightedge

Summary of Contents for 670

Page 36: ...36 ELECTRIC SCHEMATIC 67095233 ...

Page 38: ...38 PARTS LIST 6709534 MAIN BASE ASSEMBLY ...

Page 40: ...40 PARTS LIST Continued 6609529 GRINDING HEAD ASSEMBLY ...

Page 42: ...42 PARTS LIST Continued 6709531 TRAVERSE CARRIAGE ASSEMBLY ...

Page 44: ...44 PARTS LIST Continued 6709533 BEDKNIFE SUPPORT ASSEMBLY ...

Page 46: ...46 PARTS LIST Continued 6709536 CONTROL PANEL ASSEMBLY 50 ...

Page 48: ...48 PARTS LIST Continued 6709536 ELECTRICAL ASSEMBLY ...

Page 50: ...50 PARTS LIST Continued 3708784 COOLANT PUMP TANKASSEMBLY 15 ...

Page 52: ...52 ...