17

TO REPLACE THE LINEAR ACTUATOR BEARINGS

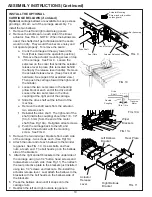

8. Slide the carriage over the actuator, and line up the

hole in the carriage with the tapped hole in the top of

the actuator block. Insert the actuator mounting screw

through the self-adjusting bearing, and tighten the screw.

9. Install the two feed screw guide mounting screws.

Install the actuator release lever into the actuator bar

assembly. Turn the actuator release lever

counterclockwise 1/2 turn to engage the actuator.

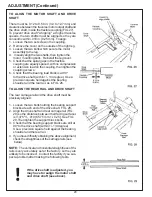

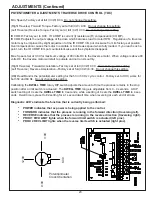

10. Connect a spring scale so it pulls on the carriage

parallel to the drive shaft. Hold the drive shaft from

rotating while you pull on the carriage. See FIG. 19.

To overcome the actuator, the pulling force should be

45 to 60 lbs (20-27 kg), with 50 lbs (23 kg) being ideal.

If not within those specifications, the actuator tension

must be adjusted. See "Adjusting the Pulling Force"

below.

Exceeding 60 lbs force won't greatly

improve drive performance - and it will

shorten the bearing life.

Adjusting the Pulling Force

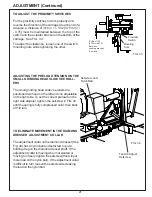

If the pulling force is not within specification (Step 10 above),

adjust it:

1. With the actuator bearings engaged to the drive shaft,

readjust the two outboard screws with springs that hold

the actuator together. To reach these screws, you must

remove the actuator bar assembly. See FIG. 17.

Turn each outboard screw an equal amount when

resetting. Turn clockwise for more tension.

2. Check the force again (repeat Step 10 above).

Continue adjusting and rechecking until within

specification.

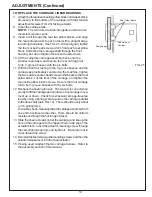

NOTE: The factory-adjusted position to reach tension

specifications is to compress the spring until there is

.22 in. (5.5 mm) clearance between the underside of

the washer and the actuator block. See FIG. 20. Use

this as a starting point unless you are already close to the

specified tension.

3. When the tension adjustment is correct, reinstall the

actuator bar assembly and actuator release lever.

ADJUSTMENTS (Continued)

FIG. 19

FIG. 20

If the actuator release lever is

tightened too much, it will

contact the outboard screw

heads and override their

adjustment, which could

cause a traverse malfunction.

Make certain that you have

full engagement when you

reengage the actuator.

Hold the drive shaft from

rotating while you check

the pulling force.

.22 (5.5mm)

Summary of Contents for 670

Page 36: ...36 ELECTRIC SCHEMATIC 67095233 ...

Page 38: ...38 PARTS LIST 6709534 MAIN BASE ASSEMBLY ...

Page 40: ...40 PARTS LIST Continued 6609529 GRINDING HEAD ASSEMBLY ...

Page 42: ...42 PARTS LIST Continued 6709531 TRAVERSE CARRIAGE ASSEMBLY ...

Page 44: ...44 PARTS LIST Continued 6709533 BEDKNIFE SUPPORT ASSEMBLY ...

Page 46: ...46 PARTS LIST Continued 6709536 CONTROL PANEL ASSEMBLY 50 ...

Page 48: ...48 PARTS LIST Continued 6709536 ELECTRICAL ASSEMBLY ...

Page 50: ...50 PARTS LIST Continued 3708784 COOLANT PUMP TANKASSEMBLY 15 ...

Page 52: ...52 ...