B2342

Emax VF

43/66

Doc. No

Model

Apparatus

Scale

Page No

1SDH000909R0001

12.3.5.3. Modules

In this section it is possible to set the Module parameters.

All parameters are available only with unit present. COM module refers to PR120/D-M (Communication module); SIGNALLING module

refers to PR120/K (Signalling module).

Module

Setting

Range

Description

COM

module

Local/Remote

Local / Remote

The change of parameters setting by user is available on

display menu, or using external communication.

Serial Address

1...247 (step 1)

Set the address

Baud rate

9600 bit/s / 19200 bit/s

Set the Baud rate

Physical protocol

8,E,1 / 8,O,1 / 8,N,2 / 8,N,1

Set the kind of byte for communication (N°bit, Parity, stop

bit).

Addressing

Modbus standard / ABB

Set the address for communication.

SIGNALLING

module

Relay n.1

- Signal Source: list

- Delay: 0.01s...100s (step 0.01s)

- Status: NO / NC

- Latched: ON / OFF

- Allow selection of events to associate with each contact.

- Set the changing status delay of contact.

- Set the normal status of the contact.

- Set the possibility to reset or to mantain the contact in

the ON position after an event.

Relay n.2

Relay n.3

Relay n.4

Input

- Polarity: active low / high

- Function: list

- Delay: 0.01s...100s (step 0.01s)

- Allow selection of the input status.

- Allow selection of the events to associate to the input

presence.

- Set the event delay associated to input.

For more details refer to the description of the module, starting from para. 12.4.

WARNING: With unit in Remote status, all parameters and settings are in read-only mode, except for the setting

Local / Remote (available to user).

With unit in Local status, all parameters and settings are in read-only mode.

WARNING: Use the address “modbus Standard” only

12.3.5.4. Datalogger

On this section is possible to set the Datalogger function parameters.

The data logger function can be used to save the instantaneous values of certain analog and digital measurements automatically in

a large-sized memory buffer. The data can easily be downloaded from the unit using either application with external module (BT030-

USB and Ekip T&P) or optional module (PR120/D-M), and transferred to any personal computer for processing.

The function allows the event to be set for recording stop, the sampling frequency and the stop delay, in order to facilitate failure analysis.

Setting

Range Value

Description

Presence

Enable / Disable

Determines the presence of the protection.

Sampling Frequency

600Hz / 1200Hz / 2400Hz / 4800Hz Determines the Sampling frequency of the signals

Stop Event

List

Allow selection of the event for recording stop for storage

Stop Delay

0s...10s (step 0.01s)

Allow setting a delay for the recording

Restart

Command

Allow reset of data recorded, and to restart the datalogger

Stop

Command

Stop recording.

By using Ekip Connect software it is possible to download the recording and to read the data.

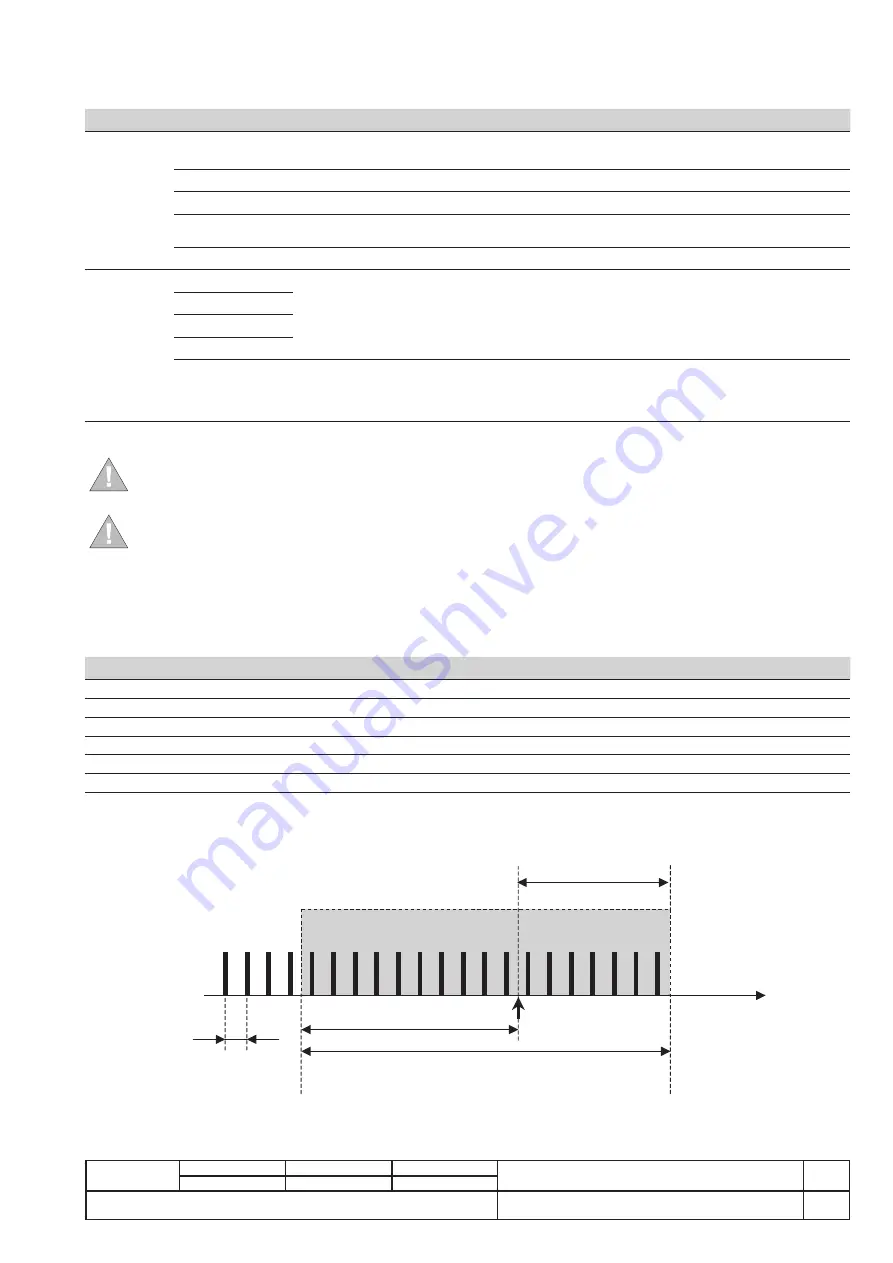

The data logger measurements are recorded in a time window, the duration of which is defined and synchronized by an event (trigger/

stop event) of your choice. The following figure displays the time window, the trigger and the samples available in grey:

Stopping

delay

Measurements available

Pretrigger

Samples

1/Freq

Trigger

Recording time