35

8

MAINTENANCE

8.4.2

Monitor Diagnostic Information

Out of Service Alarm

This alarm relay output is a normally energised relay which de-

energises in the following circumstances:

a) Loss of mains supply.

b) Calibration Failed – the calculated electrode slope value is

outside the acceptable limits or the response of the probe

is too slow. The 'CAL FAIL' l.e.d. on the front panel is

illuminated with the appropriate text on the 20-character

display.

c)

Block temperature out of limits – the measured

temperature of the Block is not within 5

°

C of the Control

Temperature. 'TEMP. CONTROL ERROR' is indicated on

the 20-character display.

d)

'OUT OF SAMPLE' alarm – a float switch in the

constant head unit detects the loss of sample. 'OUT OF

SAMPLE' is indicated on the 20-character display.

e) 'OUT OF SERVICE' alarm – displayed when the pump is

switched off.

Note.

The heater is switched off by the software when an

'OUT OF SAMPLE' condition is detected.

Calibration Fail Alarm

A calibration failed condition occurs after a two point

calibration if the calculated slope value is less than 80% or if

the probe output is unstable. The failure could be caused by a

number of factors which should be investigated.

In the 'CAL. FAILED (SLOPE)' case some indication of the

problem may be obtained from the slope value.

Slope Value Just Below 80%

a) Check liquid delivery on to the probe membrane – see

Section 8.2.7 (j).

b) Clean membrane by washing with a jet of clean water from

a wash–bottle or syringe.

c) Disassemble probe and reassemble – see Section 8.2.7.

d) Check glass electrode – see Section 8.5.

Slope Value Grossly Abnormal

a) Check, and top up as necessary, the filling solution in the

probe. There should be a 50 to 60 mm depth of solution

inside the probe.

b) Disassemble probe and reassemble – see Section 8.2.7.

c) Check glass electrode – see Section 8.5.

d) Check reference element – see Section 8.5.

Noisy, unstable response or slow response

a) Check liquid delivery on to the probe membrane – see

Section 8.2.7 (j).

b) Clean membrane by washing with a jet of clean water from

a wash–bottle or syringe.

c) Check, and top up as necessary, the filling solution in the

probe. There should be a 50 to 60 mm depth inside the

probe so that the reference element is immersed in the

solution.

d) Osmotic effects, i.e. total concentration of dissolved

species in samples too high.

e) Puncture of the membrane (usually visible), disassemble

probe and reassemble – see Section 8.2.7.

f)

Interference (from for example high concentrations of

anionic detergents).

g) Check glass electrode – see Section 8.5.

h) Check reference element – see Section 8.5.

In the 'CAL. FAILED (SLOW)' case the failure is usually due to

slow sensor response, but may be due to an unstable (noisy or

drifting) sensor output:

a) Check sensor connections in the coaxial plugs and

sockets, and inside the microprocessor unit.

b) See

Malfunction of the Electrode/Probe

– see Section

8.4.3.

8.4.3

Malfunction of the Probe

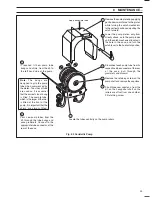

Internal Filling Solution

The internal filling solution incorporates a coloured indicator

which is normally yellow. The indicator changes to blue if the

probe membrane, or membrane seal, allows alkaline reagent

to leak into the probe. If this occurs the membrane should be

replaced, and care taken to tighten the end cap sufficiently to

provide a good seal. The solution keeps indefinitely.

8.5

General Maintenance of the Probe

8.5.1

Ageing of the Glass Electrode

After the probe has been in use for some months, the

performance of the glass electrode may eventually deteriorate

due to its continued use in weakly buffered solutions at near

neutral pH. The response of the probe becomes sluggish and

the response slope drops. The electrode may frequently be

restored to its initial condition by soaking for 12 hours in 0.1M

hydrochloric acid. The performance of the electrode may be

checked as described below.

8.5.2

Checking the Performance of the Glass

Electrode

The glass electrode may be checked independently of the

probe with a laboratory calomel reference electrode by testing

the pair in pH buffer solutions.

Immerse the glass electrode to a depth of 5 to 10 mm. There

must be no liquid contact with the reference element.