6

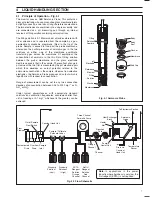

Output

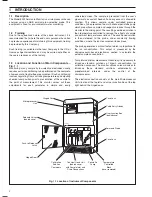

Module 1

Link for the Current

Output required

Output Module 2

(if fitted)

Temperature Input

Module

Input

Module

Protection

Plate

Captive

Screws

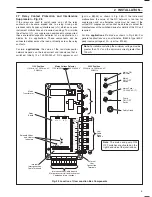

0 to 1mA

0 to 10mA

0 to 20mA

4 to 20mA

1

8

1

8

1

8 1

8

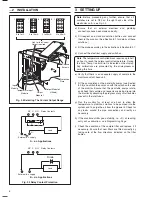

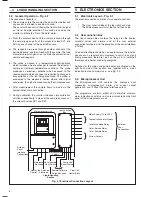

R

C

Load

L

N

External a.c. supply

Relay Contacts

NC C NO

A – a.c. Applications

Load

+

–

External d.c. supply

Relay Contacts

B – d.c. Applications

NC C NO

Diode

…2

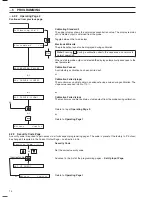

INSTALLATION

3

SETTING UP

Fig. 2.4 Selecting The Current Output Range

Fig. 2.5 Relay Contact Protection

Note.

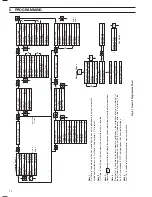

Before proceeding any further, ensure that all

switches are set to OFF on the right hand side of the

electronics unit – see Fig. 2.3.

a) Ensure that all external electrical and plumbing

connections have been made correctly.

b) Fill reagent and standard solution bottles and connect

them to the monitor. (See Section 8.1 for details of these

solutions.)

c) Fit the probe according to the instructions in Section 8.2.7.

d) Connect the electrical supply and switch on.

Note.

The temperature controlled block requires up to half

an hour to reach the normal control temperature. During

this time, 'Temp. Control Error' is indicated on the display.

Any calibrations are prevented by the microprocessor

during this time.

e) Verify that there is an adequate supply of sample to the

monitor constant head unit.

f)

Fit the pump platen on the peristaltic pumps (see Section

8.2.8) and switch the pumps on with the switch on the side

of the monitor. Ensure that the peristaltic pumps rotate,

and check that sample and reagents are being drawn into

the monitor by observing the progress of any small bubbles

present in the inlet tubes.

g) Run the monitor for at least one hour to allow the

temperature to stabilize, solutions to be pumped into the

system and to purge the air from the pipework. Check for

any leaks around the pipe connections and rectify as

necessary.

h) If the monitor exhibits good stability, i.e.

±

2% of reading,

carry out a calibration – see Programming Page.

i)

Check the condition of the sample filter and replace it if

necessary. Ensure that new filters are fitted correctly by

taking note of the flow directions indicated on the filter

bodies.