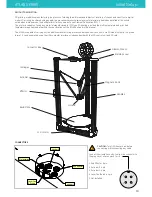

UNLOAD FILAMENT

1. Preheat the hotend to 180°C (minimum)

2. Open the extruder tension block to release the hob

3.

Pull the filament out ( use a fast moovment to reduce stringing )

Store filament in a cool place. Keep temperatures below (50° C). Keep material in sealed container or bag with moisture-absorbing

desiccant.

CHANGE FILAMENT

Filament can be changed at any time ( when the printer is idle or mid-print ).

•

The hotend must be heated to 180º C (minimum) to remove or add filament.

•

When printer is idle (not printing): Open the extruder tension block to release the hob and pull out existing filament, then follow the

Loading Filament instructions.

•

When the printer is mid-print: press the main button on the LCD Control Unit, select CUSTOM , select SD Suspend. This manually puts

the printer into standby. Then follow the Loading Filament instructions.

•

To resume the print press the main button on the LCD Control Unit, select CUSTOM , select SD Resume.

HEAT THE PRINT BED

The print bed on the ATLAS printer is heated to provide better adhesion of your printed parts. Each material you use will likely require a

different bed temperature.

• For easy removal of large or small parts, turn the bed temperature down to 20° C. You will hear the plastic loosening and the part will

pop off the print bed.

• Operate the temperature of the print bed through the LCD control unit or with 3D printing software.

See the Recommended Temperature table

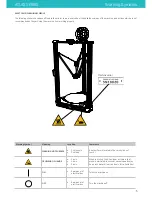

CAUTION

: For the safety of the user, use extreme caution when working with heated machinery.

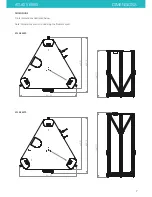

PREPARE THE PRINT BED

Prepare the build area for printing. In order for your prints to adhere to the glass ( it needs to be clear of debris and sticky ) spray a good

amount of Dimafix fixative spray onto the build area.

Cover the entire area that your print will touch. Repeat this process between prints to remove filament particles and other debris, as well

as prepare the bed for the next print.

This is not the only method available. Other suggestions include: painter’s tape, glue stick, and hairspray.

Note: 3DBNZ recommends using Dimafix or 3DLAC only. Any scented hairspray may contain oils and cause adherence

issues on the print bed.

Do not use glass cleaner or alcohol on the glass. Doing so will make adhesion very difficult.

For big prints the fixative spray should be sprayed while the glass build plate is removed from the printer in order to avoid contaminations

of sticky material on the delta motion system.

•

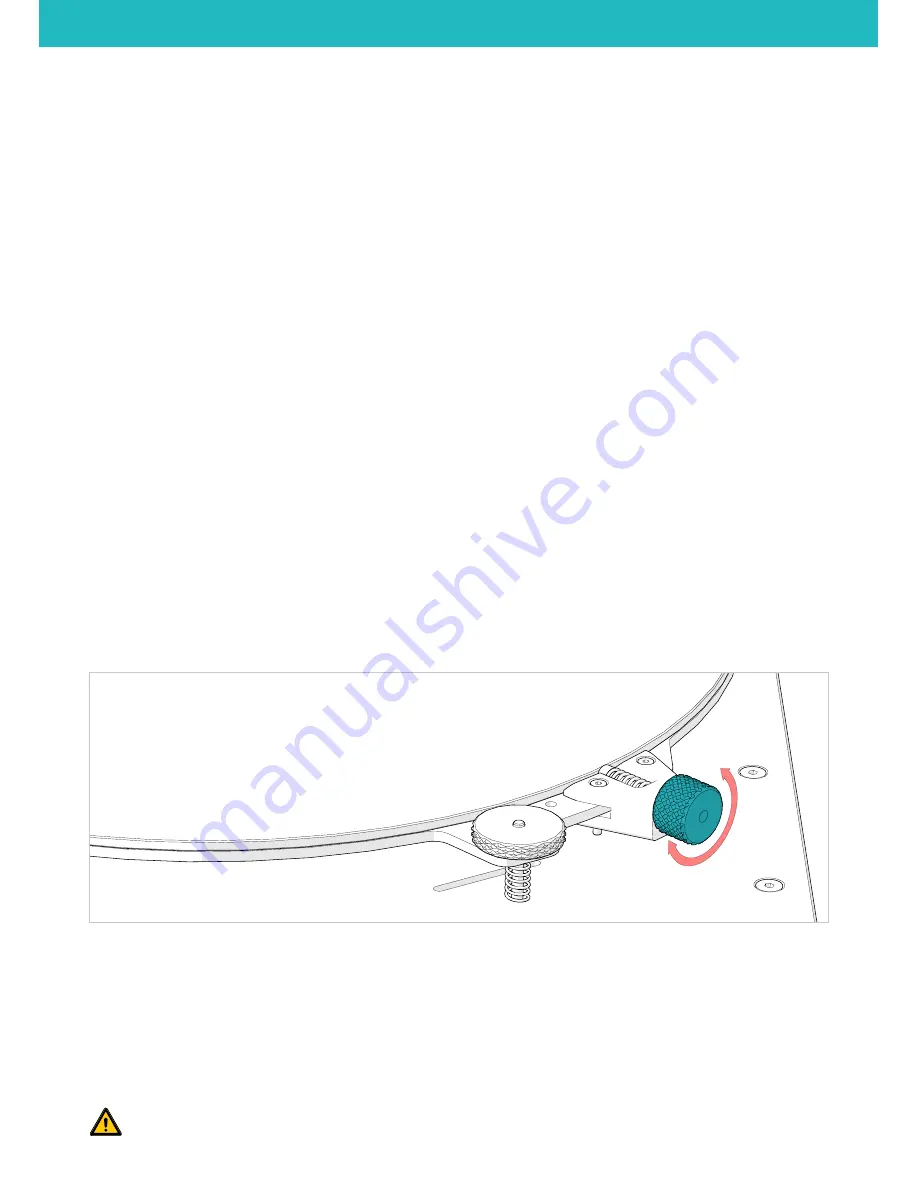

To remove the glass turn clockwise the glass retention knob to release pressure of the spring

•

Clean the aluminium contact surfaces and the back of the glass before installing it into the printer

ATLAS SERIES

Initial Setup

16