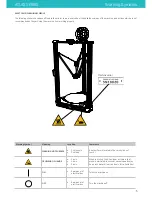

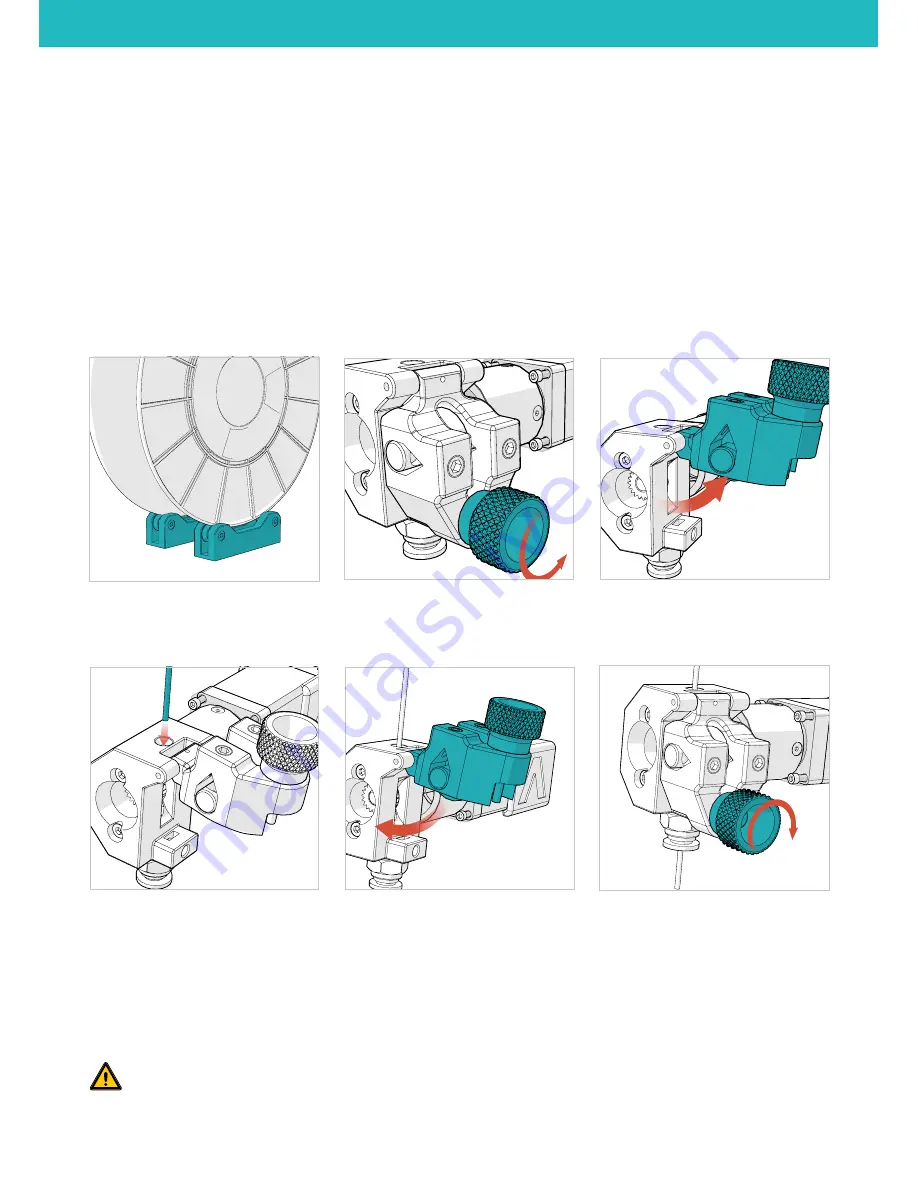

LOAD FILAMENT AND EXTRUDER TEST

Position the filament spool roller on top of the printer. Guide the filament through the first PTFE tube then into the extruder.

1.

Lower the End effector to make the loading operations easier.

LCD > CUSTOM > LOADING POSITION

2. Pre heat the 3D printer

LCD > PREPAE > PREHEAT

3. Set the nozzle temperature 10°C above the reccomended for the used material.

LCD > PREPARE > SET TEMPERATURES > HOTEND

4.

While waiting temperature to stabilize load the filament

5. Push the filament by hand into the extruder until you see material flowing from the nozzle.

The filament must flow consistetly without applyng to much force. Adjust temperature so the force needed to push the filamnent in is not

too high.

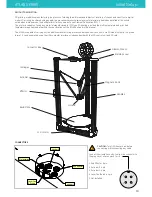

6. Turn the knob until the extruder block is fully closed.

IMPORTANT:

Do not overtight the knob

Depending on filament elasticity you can adjust the tensioner force by turning the two hex screws.

Tighten for hard materials and loosen for softer ones.

7. Test for consistent flow by extruding 4/5 timens 10mm of filament

LCD > CUSTOM > EXTRUDE 10mm

CAUTION:

Do not RETRACT more than 3mm of filament or the hot end will jam.

ATLAS SERIES

Initial Setup

15