COMPUTER-CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE

- 45

-

.

⑶

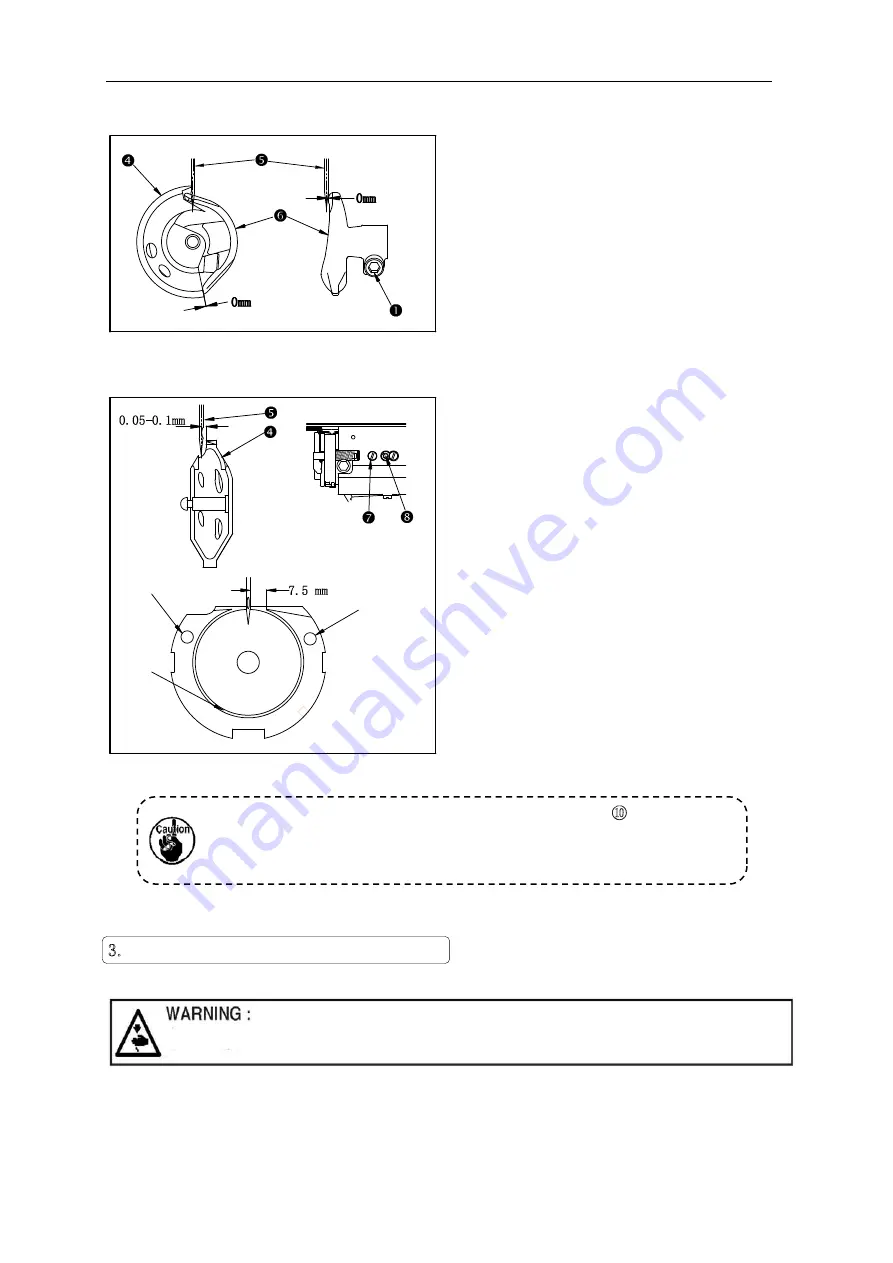

Adjust so that the blade point of inner

hook

④

aligns with the center of needle

⑤

,

and that a clearance of 0 mm is provided

between the front end of the driver and the

needle as the front end face of driver

⑥

receives the needle to prevent the needle

from being bent. Then tighten setscrew

①

of

.

⑷

Loosen setscrew

⑦

of the shuttle, and

adjust the longitudinal position of the

shuttle. To do this adjustment, turn shuttle

race adjusting shaft

⑧

clockwise or

counterclockwise to provide a 0.05 to 0.1

mm clearance between needle

⑤

and the

blade point of inner hook

④

.

.

⑸

After adjusting the longitudinal position

of the shuttle, further adjust to provide a

7.5 mm clearance between the needle and

the shuttle by adjusting the rotating

direction. Then tighten setscrew

⑦

of the

shuttle.

Apply a small amount of oil to race section

⑨

and oil wick

⑩

, and use the

sewing machine after an extended period of disuse or cleaning the

periphery of hook portion.

●

10

●

10

●

9

3.

Adjusting the lift of the work clamp foot

Turn OFF the power before starting the work so as to prevent accidents

cause by abrupt start of the sewing machine.

Содержание ZJ1900DSS

Страница 6: ...高速电子套结机 2 各部件名称 1 主机的名称 缝纫机机头 送布压脚 线架 操作面板 电源开关 脚踏开关 2 2 1 2 5 3 2 6 2 4 2 7 机架 ...

Страница 9: ...高速电子套结机 5 7 电线的连接 脚踏板 操作面板 8 眼睛防护罩的安装 为防止断针飞起弄伤眼睛 请一定安装起来 将附件箱中眼睛防护罩装在机头 如图所示左侧 ...

Страница 25: ...高速电子套结机 21 图1 ...

Страница 67: ...高速电子套结机 Ⅵ 台板图纸 63 Ⅱ ...

Страница 96: ...COMPUTER CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE 25 图1 ...

Страница 97: ...6 ...

Страница 146: ...COMPUTER CONTROLLED HIGH SPEED LOCKSTITCH BAR TACKING MACHINE 75 Ⅵ DRAWING OF THE TABLE Ⅱ ...