page 24

enGlisH

Legacy™ Model LRZM Pool/Spa Heater

|

Installation and Operation Manual

8.3.2 relighting the Heater

If the pilot goes out, repeat steps 5 through 7 in

Section 8.3.1.

8.3.3 shut-down procedure

1. To turn the main burner off, turn the rocker

switch to OFF.

2. To turn the heater off (including the pilot), turn

the gas valve knob to the OFF position.

8.4

turning the Heater on/off and

setting the temperature Control

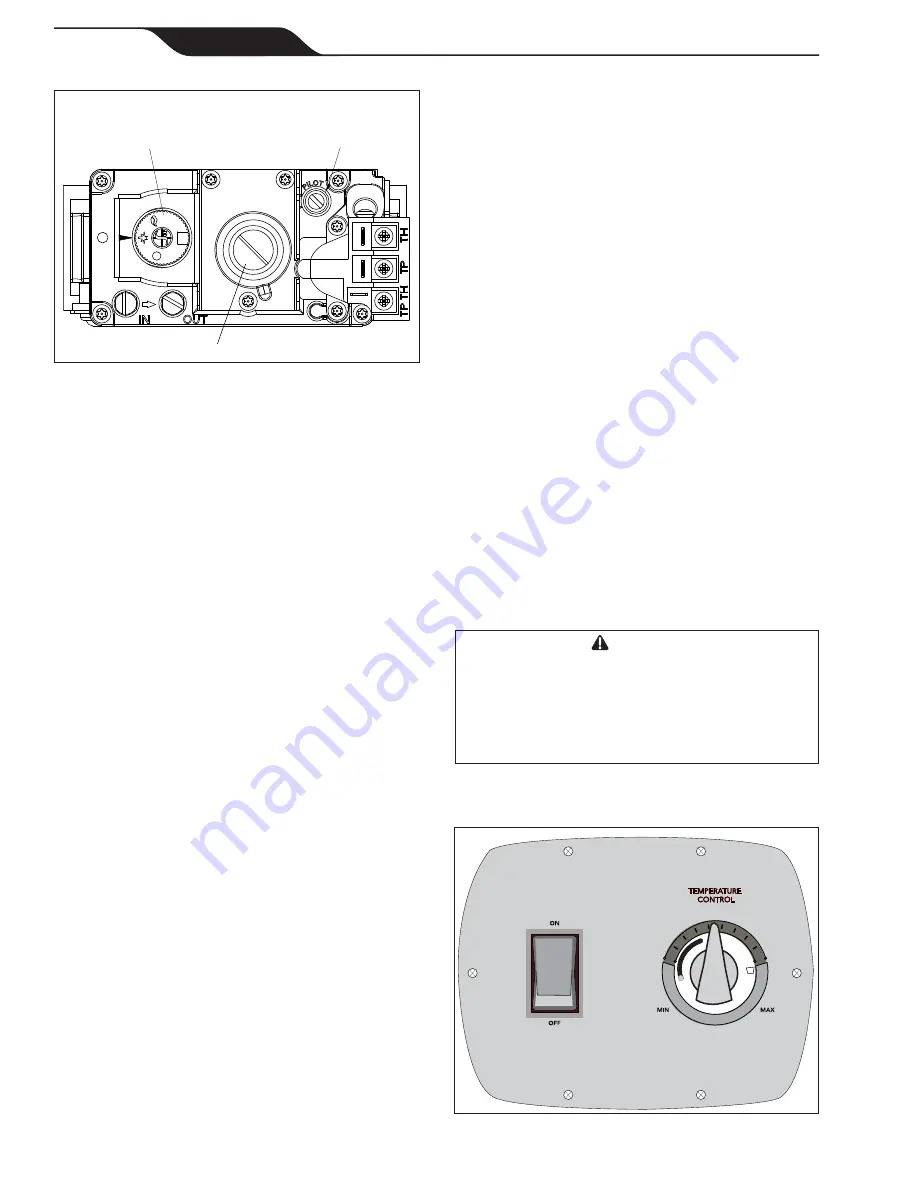

The temperature control (see Figure 20) is

calibrated at the factory and covers a range from

approximately 21°C to 40°C (70°F to 104°F). Use an

accurate pool thermometer to determine the best water

temperature for your use.

The Legacy temperature control panel has a

rocker switch to turn the heater on and off. It also has

a rotary dial to set the desired thermostat setting (see

Figure 20).

Once the heater has been lit by following the

safety and lighting procedures in Section 8.3, set the

toggle switch on the control panel to "ON" to start the

heater operation. If the heater senses that the pump

is on and the thermostat setting is higher than the

temperature of the pool/spa water, the pilot will ignite

the main burners.

Caution

In order to prevent property damage, the heater is

designed to run only when the filter pump is run

-

ning. If the heater does not immediately turn off

when the pump turns off, turn the heater off at the

control panel. The heater's pressure switch may

need adjusting (see Section 11.5)

2. Turn the gas control knob clockwise until it stops

at the OFF position (see Figure 19).

3. Wait five (5) minutes before lighting the pilot.

4. Turn the knob on the gas valve counterclockwise

to PILOT, then push the control knob all the way

and hold down. Push the button of the sparker,

repeating until confirming that the pilot lights by

observing the reflection on the burner tray mirror.

Continue to hold the control knob in for about

one (1) minute after the pilot is lit. If it goes out,

repeat Steps 3 and 4.

5. Release the control knob and verify that the pilot

is lit.

6. If the pilot burner does not remain lit when the

button is released, press and release the red

button. Wait at least three (3) minutes and then

repeat the lighting procedure from step 4.

7. If the pilot cannot be established, check that the

pilot burner flame correctly envelops the thermo

-

couple tip by 10 to 13 mm. If not, check that the

pilot adjustment screw on the gas control (see

Figure 19) is fully unscrewed, then turn it one (1)

turn back in. Check that the thermocouple lead

connections at the gas control and at the overheat

thermostat are clean and secure. Repeat from

Step 4.

8. Turn gas valve knob to ON. Replace the service

door.

9. Turn the rocker switch to ON.

10. Set temperature control to against the Temp-Lok

tab. The main burner should light. Until the water

reaches a temperature of about 21°C (70°F), it is

normal to have some water accumulating in the

base of the heater.

11. Set the time clock, if one is installed.

Figure 20. temperature Control

H0286600

Figure 19. natural Gas/propane Control Valve

Control Knob

with OFF, Pilot

and ON Position

Regulator

Pilot Adjustment

Содержание Legacy LRZ

Страница 2: ......