Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

10

11

Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

INSTALLATION AND OPERATING INSTRUCTIONS:

Rotary clamping element hydraulic DKHS1000 series

INSTALLATION AND OPERATING INSTRUCTIONS:

Rotary clamping element hydraulic DKHS1000 series

EN / 2021-03-09

DDOC00230 / f

EN / 2021-03-09

DDOC00230 / f

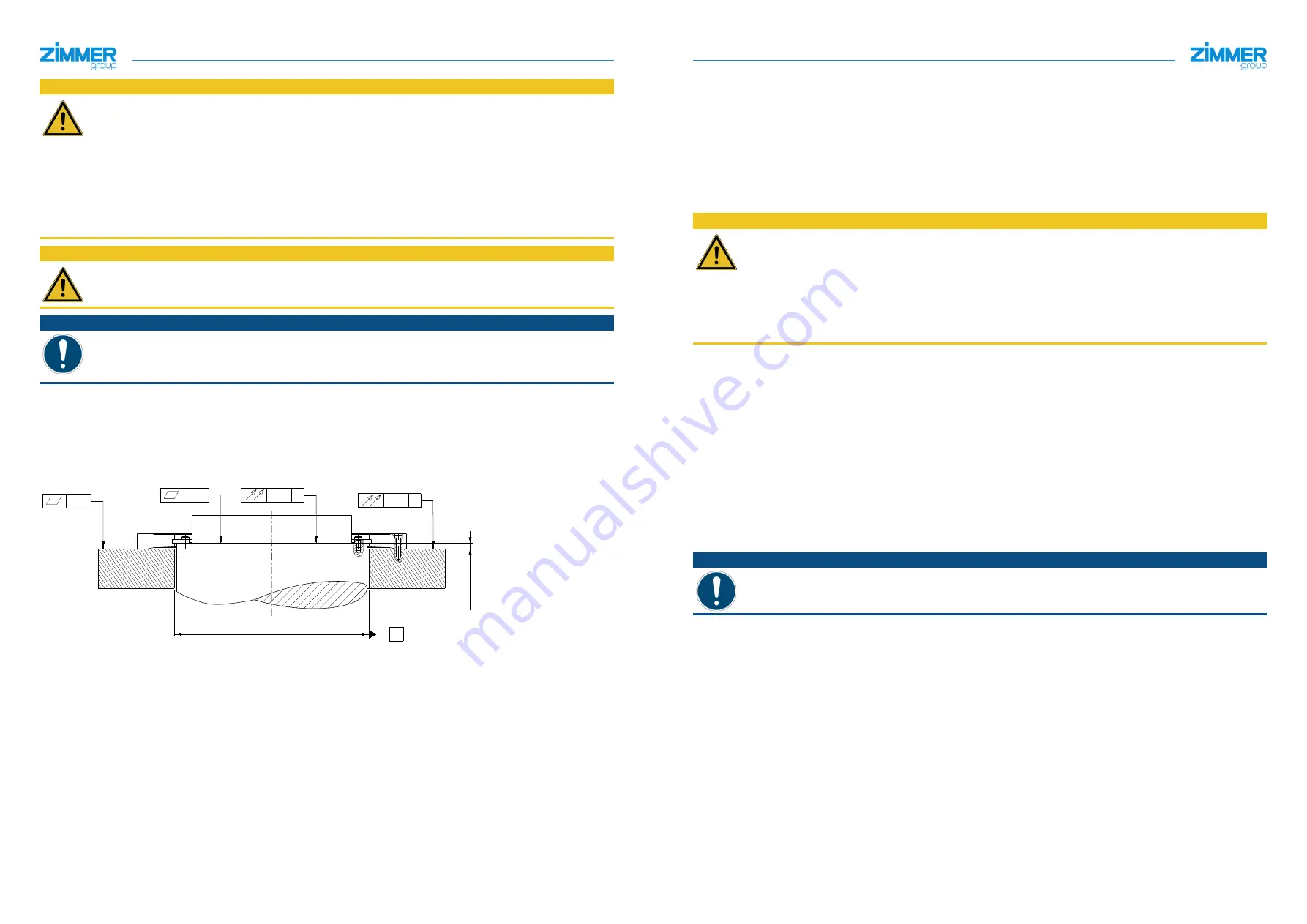

MOUNTING SURFACES

Mounting surface of the housing:

Ö

Outer diameter of the product – 40 mm

The minimum mounting surface with which the product may be mounted to the mounting piece is minus 40 mm

of the outside diameter of the product housing.

Mounting surface of the shaft connection:

Ö

Inner diameter of the shaft conn 40 mm (m 22 mm)

The minimum mounting surface with which the product may be mounted to the shaft bracing is plus 22 mm of

the inner diameter of the product shaft connection.

Zimmer GmbH recommends a mounting surface of + 40 mm!

SURFACE ROUGHNESS

The flat surface must have a minimum roughness of Ra 1.6.

Ö

O-ring and cutting ring

NOTICE

Vertical installation:

The bleed connection C must be facing upwards for a vertical installation.

Ö

The built-in sealing plug of the bleed connection C is not suitable for sealing!

The following work steps must be observed when installing at the mounting piece

bm

:

►

Before mounting the product, the pressure setting and operability of the pressure relief valve must be checked.

►

The product must be installed on an appropriate mounting surface in accordance with the levelness and total run-out

specifications.

Ö

Permissible unevenness and total run-out of < 0.02 mm

Ö

Make sure the mounting surface is sufficiently rigid and flat.

0.02

0.01 A

A

0.02

0.01 A

A

bstimmmaß

►

Adjust the shim

bn

to the specified adjustment dimension.

Ö

Refer to the laser marking on the product for the adjustment dimension.

►

Check whether all cutting rings and O-rings are properly inserted in the product.

► Remove the sealing plugs from the hydraulic connections A

5

and bleed connection C

6

.

► Set the product onto the

bn

shim

and mounting piece

bm

.

Ö

Ensure that the hydraulic connection A

5

and

the bleed connection C

6

sit on the spotfaces.

►

Loosely attach the housing

1

and

shaft connection

8

using the mounting screws

bl

to the mounting piece

bm

and

shim

bn

.

CAUTION

Under no circumstances may the product be pressurized before all screws are tightened with the necessary

tightening torque.

Ö

Screw-in depth = at least 1.2. x Ø

Ö

The mounting screws are not included in the scope of delivery.

Ö

Strength class of the mounting screws at least 12.9

Ö

DIN EN ISO 4762.

Ö

The product is centered via the screw fittings.

Ö

Maximum tolerance of the shim ± 5 µm.

►

Tighten the mounting screws

bl

with the specified tightening torque to the mounting piece

bm

.

►

Tighten the mounting screws

bl

on the housing first, then on the shaft connection.

► Observe the tightening torques of the mounting screws

bl

.

►

Tighten the mounting screws

bl

crosswise.

►

Bleed the product by flushing it with hydraulic oil HLP46.

Ö

Hydraulic connection A = Pressurization

Ö

Bleed connection C = Venting

►

Add hydraulic oil to the product at low pressure using hydraulic connection A

5

► Flush the product until the hydraulic oil escapes from the bleed connection C

6

.

► Seal the bleed connection C

6

at mounting piece

bm

using a suitable pressure-resistant closure.

► Carry out a functional check.

Ö

The procedure of the functional test is described in section "Function check".

NOTICE

Non-compliance may result in material damage.