ZIMM Actuator

6 Installation

2023

Version 0.6

23

6.7

Commissioning

The ZIMM Actuator together with its attachments must be

installed and connected.

Spindle and anti-rotation lock lubricated (for more

information see section "7.2 Lubrication”, page 25).

The trial run must have been completed successfully.

CAUTION

High forces are generated!

Damage to the ZIMM Actuator.

Make sure that the limit switch (optional) and end bearings are not

overrun.

Make sure that attachments do not collide with other parts.

HINWEIS

Make sure that the mechanism that is actuated can move along

the entire stroke path.

1. Check all screw fastenings once again.

2. Perform a trial run with operating load.

When doing this, comply with the following:

– Torque must be constant.

– Current consumption must be constant.

– Operating temperature must be within the normal range.

– The limit switch (if fitted) or the end bearings must not be

overrun.

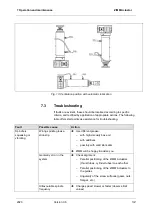

3. If a safety nut SIFA is available. Measure and note down

dimension "A" (see fig. 20). This dimension in new condition

serves as a comparative measure in the further course of

operation in order to be able to evaluate the wear

(see

chapter 7.1.1.)

6.8

Running-in phase

The running-in phase of the ZIMM Actuator lasts as a rule between 20 and

50 operating hours. A higher torque and higher operating temperature

must be expected during this period.

The torque may be up to 50% higher during the running-in phase than in

subsequent operation.

Содержание ZA-25

Страница 33: ......

Страница 35: ...11 Declaration of incorporation...