21

JOHNSON CONTROLS

SECTION 2 – PRODUCT DESCRIPTION

FORM 150.67-NM1

ISSUE DATE: 4/28/2017

2

Unit On/Off Switch

The microprocessor control center is capable of dis-

playing the following:

•

Return and leaving liquid temperature

•

Low leaving liquid temperature cutout setting

•

Low ambient temperature cutout setting

•

Outdoor air temperature

•

English or Metric data

•

Suction pressure cutout setting

•

Each system suction pressure

•

Discharge pressure (optional)

•

Liquid Temperature Reset via a YORK ISN DDC

or Building Automation System (by others) via:

•

a pulse width modulated (PWM) input as

standard.

•

a 4 to 20 milliamp or 0 to 10 VDC input with

the optional B.A.S. interface option.

•

Anti-recycle timer status for each system

•

Anti-coincident system start timer condition

•

Compressor run status

•

No cooling load condition

•

Day, date and time

•

Daily start/stop times

•

Holiday status

•

Automatic or manual system lead/lag control

• Lead system definition

•

Compressor starts and operating hours

(each compressor)

•

Status of hot gas valves, evaporator heater and fan

operation

•

Run permissive status

* Intensity of Protection European Standard

** International Electrotechnical Commission

•

Number of compressors running

•

Liquid solenoid valve status

•

Load and unload timer status

•

Water pump status

Provisions are included for:

•

Pumpdown at shutdown.

•

Optional remote chilled water temperature reset.

•

Two steps of demand load limiting from an exter-

nal building automation system.

Unit alarm contacts are standard.

The operating program is stored in non-volatile mem-

ory (EPROM) to eliminate chiller failure due to AC

powered failure/battery discharge. Programmed set-

points are retained in lithium battery-backed RTC

memory for 5 years minimum.

COMMUNICATIONS

•

Native communication capability for BACnet

(MS/TP) and Modbus

•

Optional communication available for N2 and

LON via eLink option

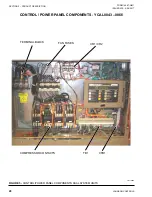

POWER PANEL

Each panel contains:

•

Compressor power terminals

•

Compressor motor starting contactors per l.E.C.**

•

Control power terminals to accept incoming for

115-1-60 control power

•

Fan contactors and overload current protection

The power wiring is routed through liquid-tight con-

duit to the compressors and fans.

Содержание YCAL0019

Страница 4: ...JOHNSON CONTROLS 4 FORM 150 67 NM1 ISSUE DATE 4 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 14: ...JOHNSON CONTROLS 14 FORM 150 67 NM1 ISSUE DATE 4 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 69: ...69 JOHNSON CONTROLS SECTION 5 TECHNICAL DATA FORM 150 67 NM1 ISSUE DATE 4 28 2017 5 5...

Страница 71: ...71 JOHNSON CONTROLS SECTION 5 TECHNICAL DATA FORM 150 67 NM1 ISSUE DATE 4 28 2017 5 5...

Страница 127: ...127 JOHNSON CONTROLS SECTION 5 TECHNICAL DATA FORM 150 67 NM1 ISSUE DATE 4 28 2017 5 5 DIMENSIONS YCAL0052 SI CONT D...

Страница 129: ...129 JOHNSON CONTROLS SECTION 5 TECHNICAL DATA FORM 150 67 NM1 ISSUE DATE 4 28 2017 5 5 DIMENSIONS YCAL0056 SI CONT D...

Страница 191: ...191 JOHNSON CONTROLS SECTION 8 UNIT OPERATION FORM 150 67 NM1 ISSUE DATE 4 28 2017 8 Figure 48 WIRING LD11799A...

Страница 202: ...JOHNSON CONTROLS 202 FORM 150 67 NM1 ISSUE DATE 4 28 2017 SECTION 8 UNIT OPERATION THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 229: ...229 JOHNSON CONTROLS SECTION 10 MAINTENANCE FORM 150 67 NM1 ISSUE DATE 4 28 2017 NOTES...