661693-UIM-E-1212

6

Johnson Controls Unitary Products

Please refer to Outdoor Unit Tech Guide to verify which TXV is installed

in this coil and that this is a valid system match for the AC or HP unit

installed.

The temperature sensing bulb is attached to the coil suction header

line. See Figure 11.

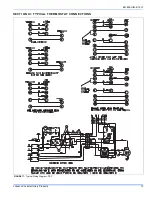

REFRIGERANT LINE CONNECTION

Connect lines as follows:

1.

Suction and liquid line connections are made outside the cabinet.

Leave the tubing connection panel attached to the cabinet with the

tubes protruding through it. Coil access panel should be removed

for brazing. The lines are swedged to receive the field line set

tubes.

2.

Remove the heat shield from the Customer Packet, soak in water,

and install over coil tubing to prevent overheating of cabinet.

3.

Wrap a water soaked rag around the coil connection tubes inside

the cabinet to avoid damaging the TXV bulb.

4.

Remove grommets where tubes exit the cabinet to prevent burning

them during brazing.

5.

Purge refrigerant lines with dry nitrogen.

6.

Braze the suction and liquid lines. Suction line must be insulated.

7.

Remove the heat shield.

8.

Re-attach the grommets to the lines carefully to prevent air leakage.

9.

Attach the coil access panel to the cabinet.

Refer to Outdoor unit Installation Manual for evacuation, leak check and

charging instructions.

Lines should be sound isolated by using appropriate hangers or strap-

ping.

All evaporator coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or

equivalent. DO NOT use soft solder.

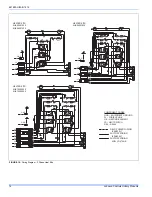

DRAIN CONNECTIONS

All drain lines should be trapped a minimum of three inches, should be

pitched away from unit drain pan and should be no smaller than the coil

drain connection.

Route the drain line so that it does not interfere with accessibility to the

coil, air handling system or filter and will not be exposed to freezing

temperatures. See Figure 2 for drain connection locations.

Coils should be installed level or pitched slightly toward the drain end.

Suggested pitch should not exceed 1/4 inch per foot of coil.

The coil is provided with a secondary drain that should be trapped and

piped to a location that will give the occupant a visual warning that the

primary drain is clogged. If the secondary drain is not used it must be

capped.

The drain pan connections are designed to ASTM Standard D 2466

Schedule 40. Use 3/4" PVC or steel threaded pipe. Since the drains are

not subject to any pressure it is not necessary to use Schedule 40 pipe

for drain lines.

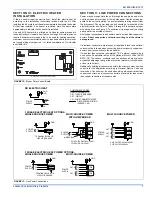

FIGURE 11:

Proper Bulb Location

COIL UNDER PRESSURE.

Relieve pressure by depressing schrader core. Coil requires orifice or

TXV to be added. See outdoor unit documentation for correct orifice

or TXV to be used. Refer to unit nameplate for orifice or TXV identifi-

cation for this unit.

The coil should be open to the air for no more than 2 minutes to keep

moisture and contaminates from entering the system. If the coil can-

not be brazed into the refrigeration system in that time, the ends

should be temporarily closed or plugged. For a short term delay, use

masking tape over the ends of the copper tubing to close the tube to

the air. For a longer term delay, use plugs or caps. There is no need

to purge the coil if this procedure is followed.

Dry nitrogen should always be supplied through the tubing while it is

being brazed, because the temperature required is high enough to

cause oxidation of the copper unless an inert atmosphere is provided.

The flow of dry nitrogen should continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only

low pressure dry nitrogen is introduced into the tubing. Only a small

flow is necessary to displace air and prevent oxidation.

Route the refrigerant lines to the coil in a manner that will not obstruct

service access to the coil, air handling system, or filter.

TXV BULB

(Cover completely

with insulation)

SCREW

CLAMP

NUT

SUCTION LINE

NOTICE

NOTICE

ALWAYS evacuate the coil and line. Set tubing to 500

microns before opening outdoor unit service valves.

Threaded drain connection should be hand-tightened, plus no more

than 1/16 turn.

When the coil is installed in an attic or above a finished ceiling, an

auxiliary drain pan should be provided under the coil if specified by

local building codes. When this exterior secondary drain pan is used

that drain should be piped to a location that will give the occupant a

visual warning that the primary drain is clogged.

NOTICE

Содержание 41HP AHR18B

Страница 1: ......