661693-UIM-E-1212

8

Johnson Controls Unitary Products

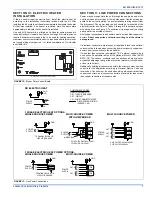

SECTION VI: LOW VOLTAGE CONTROL

CONNECTIONS

The 24 volt power supply is provided by an internally wired low voltage

transformer which is standard on all models, However, if the unit is con-

nected to a 208 volt power supply, the low voltage transformer must be

rewired to the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can exit the unit on the top right hand

corner or the right hand side panel. Refer to Figure 2.

Remove desired knockout and pierce foil faced insulation to allow wir-

ing to pass through. Use as small of a hole as possible to minimize air

leakage. Install a 7/8” plastic bushing in the selected hole and keep low

voltage wiring as short as possible inside the control box.

To further minimize air leakage, seal the wiring entry point at the outside

of the unit.

The field wiring is to be connected at the pigtails supplied with the con-

trol board harness. Refer to SECTIONS X and XI for system wiring.

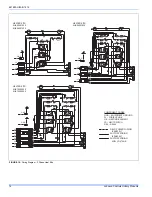

SECTION VII: BLOWER SPEED

CONNECTIONS

Adjust blower motor speed to provide airflow within the minimum and

maximum limits approved for evaporator coil, electric heat and outdoor

unit. Speed tap adjustments are made at the motor terminal block. Air-

flow data is shown in Table 10.

Connect motor wires to motor speed tap receptacle for speed desired.

See unit wiring label for motor wiring details.

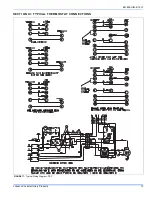

SECTION VIII: UNIT DATA

All wiring must comply with local and national electrical code require-

ments. Read and heed all unit caution labels.

It is possible to vary the amount of electric heat turned on during the

defrost cycle of a heat pump. Standard wiring will only bring on the

first stage of electric heat during defrost. See Table 5 for additional

information on heat during defrost cycle.

NOTICE

NOTICE

FIGURE 14:

Blower Speed Connections

FACTORY WIRED TO

TRANSFORMER

FACTORY WIRED TO

FAN MOTOR RELAY

TERMINAL ON

CONTROL BOARD

PUR

PU

R

HIGH

MED

LOW

GND.

230 VOLT

BLOWER MOTOR

AHR STANDARD MOTOR

CAP

BRN

BLK

TABLE 2:

Physical and Electrical Data

Models

AHR18B

AHR24B

AHR30B

AHR36B

AHR42C

AHR48D

AHR60D

Blower - Diameter x Width

10 x 8

10 x 8

10 x 8

10 x 8

10 x 10

10X10

10X10

Motor

HP

1/4 HP

1/4 HP

3/4 HP

3/4 HP

3/4 HP

3/4 HP

3/4 HP

Nominal RPM

1075

1075

1075

1075

1075

1075

1075

Voltage

208/230

208/230

208/230

208/230

208/230

208/230

208/230

Full Load Amps @230V

1.4

1.4

3.0

3.0

3.0

3.0

3.0

Filter

1

Type

DISPOSABLE OR PERMANENT

Size

16 x 20 x 1

16 x 20 x 1

16 x 20 x 1

16 x 20 x 1

20 x 20 x 1

22 x 20 x 1

22 x 20 x 1

Permanent Type Kit

1PF0601BK 1PF0601BK 1PF0601BK

1PF0601BK

1PF0602BK

1PF0603BK

1PF0603BK

Shipping / Operating Weight (lbs.)

112/100

117/102

117/105

122/110

148/133

165/147

168/150

1. Field Supplied.

TABLE 3:

Electrical Data - Cooling Only

Models

Motor FLA

1

Minimum Circuit Ampacity

MOP

2

Minimum Wire Size

(AWG)

3

AHR18B / AHR24B

1.4

1.8

15

14

AHR30B / AHR36B /

AHR42C / AHR48D /

AHR60D

3.0

3.8

15

14

1. FLA = Full Load Amps

2. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

3. 75

C, copper wire only. If wire other than non-plated, 75

C ambient, copper wire is used, consult applicable tables of the NEC and local codes..

Содержание 41HP AHR18B

Страница 1: ......