661693-UIM-E-1212

Johnson Controls Unitary Products

3

SECTION III: UNIT INSTALLATION

CLEARANCES

Clearances must be taken into consideration, and provided for as fol-

lows:

1.

Refrigerant piping and connections - minimum 12” recommended.

2.

Maintenance and servicing access - minimum 36” from front of unit

recommended for blower motor / coil replacement.

3.

Condensate drain lines routed to clear filter and panel access.

4.

Filter removal - minimum 36” recommended.

5.

The ductwork and plenum connected to this unit are designed for

zero clearance to combustible materials.

6.

A combustible floor base accessory is available for downflow appli-

cations of this unit, if required by local code.

LOCATION

Location is usually predetermined. Check with owner’s or dealer’s

installation plans. If location has not been decided, consider the follow-

ing in choosing a suitable location:

1.

Select a location with adequate structural support, space for service

access, clearance for air return and supply duct connections.

2.

Use hanging brackets to wall mount this single piece air handler

unit, is not recommended.

3.

Normal operating sound levels may be objectionable if the air han-

dler is placed directly over some rooms such as bedrooms, study,

etc.

4.

Select a location that will permit installation of condensate line to an

open drain or outdoors allowing condensate to drain away from

structure.

The coil is provided with a secondary drain. It should be piped to a loca-

tion that will give the occupant a visual warning that the primary drain is

clogged. If the secondary drain is not used it must be capped.

5.

When an evaporator coil is installed in an attic or above a finished

ceiling, an auxiliary drain pan should be provided under the air han-

dler as is specified by most local building codes.

6.

Proper electrical supply must be available.

7.

If unit is located in an area of high humidity (i.e. an unconditioned

garage or attic), nuisance sweating of casing may occur. On these

installations, unit duct connections and other openings should be

properly sealed, and a wrap of 2” fiberglass insulation with vinyl

vapor barrier should be used.

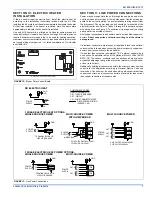

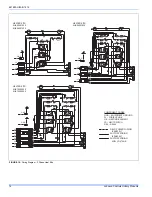

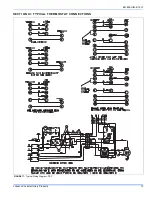

FIGURE 2:

Dimensions & Duct Connection Dimensions

J

D

Blower

Compartment

Circuit Breaker

Panel

Drain Pan Connections

for Horizontal Applications

Refrigerant

Connections

Drain Connections

for Upflow

Applications

7-11/32”

B

A

K

C

1-1/2”

Top Outlet

Dimensions

Filter

Access

18-9/32”

E

Bottom Inlet

Dimensions

13”

F

TABLE 1:

Dimensions

1

Models

Dimensions

Wiring Knockouts

2

Refrigerant

Connections

Line Size

A

B

C

D

E

F

J

K

Height

Width

Depth

Power

Control

Liquid

Vapor

AHR18B/AHR24B/

AHR30B/AHR36B

46

17 1/2

21 1/2

16 1/2

13-29/32

16 1/2

7/8 (1/2)

1-3/8(1)

1-23/32 (1-1/4)

7/8 (1/2)

3/8

3/4

AHR 42C

52

21

21 1/2

17-13/32

20

AHR48D/AHR60D

57

24 1/2

26

20-29/32

23-1/2

7/8

1. All dimensions are in inches.

2. Actual size (conduit size).

The primary and secondary drain line must be trapped to allow proper

drainage of condensate water. If the secondary drain line is not used,

it must be capped.

NOTICE

Содержание 41HP AHR18B

Страница 1: ......