661693-UIM-E-1212

Johnson Controls Unitary Products

7

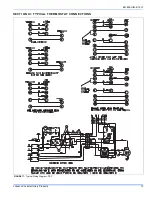

SECTION IV: ELECTRIC HEATER

INSTALLATION

If the air handler requires electric heat, install the electric heat kit

according to the installation instructions included with the kit. After

installing the kit, mark the air handler nameplate to designate the heater

kit that was installed. If no heater is installed, mark the name plate

appropriately to indicate that no heat kit is installed.

Use only 6HK heater kits, as listed on Air Handler name plate and in

these instructions. Use data from Tables 4 through 9 for information on

required minimum motor speed tap to be used for heating operation,

maximum over-current protection device required and minimum electri-

cal supply wiring size required – for listed combination of Air Handler

and Heater Kit.

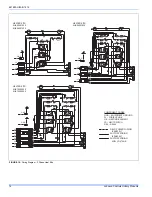

SECTION V: LINE POWER CONNECTIONS

Power may be brought into the unit through the supply air end of the

unit (top when unit is vertical) or the left side panel. Use the hole appro-

priate to the unit’s orientation in each installation to bring conduit from

the disconnect. The power lead conduit should be terminated at the

electrical control box. Refer to Tables 6 throught 9 to determine proper

wire sizing. Also see Figure 2. To minimize air leakage, seal the wiring

entry point at the outside of the unit.

All electrical connections to air handlers must be made with copper con-

ductors.

Direct connection of aluminum wiring to air handlers is

not approved.

If aluminum conductors are present, all applicable local and national

codes must be followed when converting from aluminum to copper con-

ductors prior to connection to the air handler.

If wire other than uncoated (non-plated), 75° C ambient, copper wire is

used, consult applicable tables of the National Electric Code (ANSI/

NFPA 70). The chosen conductor and connections all must meet or

exceed the amperage rating of the overcurrent protector (circuit breaker

or fuse) in the circuit.

Additionally, existing aluminum wire within the structure must be sized

correctly for the application according to National Electric Code and

local codes. Caution must be used when sizing aluminum rather than

copper conductors, as aluminum conductors are rated for less current

than copper conductors of the same size.

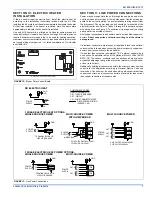

FIGURE 12:

Blower Delay Control Board

AHR/PSC CONTROL BOARD

FIGURE 13:

Line Power Connections

*1'

*1'

/8*

FIELD POWER WIRING

(208/230-1-60)

-803(5%$5

NO ELECTRIC HEAT

COMPONENT CODES

GND

–

GROUND LUG

CB

–

CIRCUIT BREAKER

CKT - CIRCUIT

CN

–

WIRE CONNECTOR/NUT

32:(5

6833/<

CKT 1

1 PHASE ELECTRIC HEAT OPTIONS:

SINGLE SOURCE POWER

MULTI-SOURCE POWER

MULTI-SOURCE POWER

WITH JUMPER BAR

TERMINAL BLOCK OR

CIRCUIT BREAKER

POWER

SUPPLY

POWER

SUPPLY

3 PHASE ELECTRIC HEAT POWER OPTIONS:

SINGLE SOURCE POWER

MULTI-SOURCE POWER

2 CIRCUITS ON13KW-20KW

3 CIRCUITS ON 25KW

TERMINAL BLOCK OR

CIRCUIT BREAKER

CKT 2

CKT 1

POWER

SUPPLY

CB

CB

CB

CB

CB

2 CIRCUITS ON13KW-20KW

3 CIRCUITS ON 25KW

POWER

SUPPLY

*1'

*1'

*1'

*1'

POWER

SUPPLY

L1

L2

L1

L2

L1

L2

CKT 2

CKT 3

L1

L2

L1

L2

CN

CN

CB

CB

CB

L1

L2

L3

L1

L2

L3

L1

L2

L3

Содержание 41HP AHR18B

Страница 1: ......