6.1 Error Detection Function

6-3

HW0480311

HW0480311

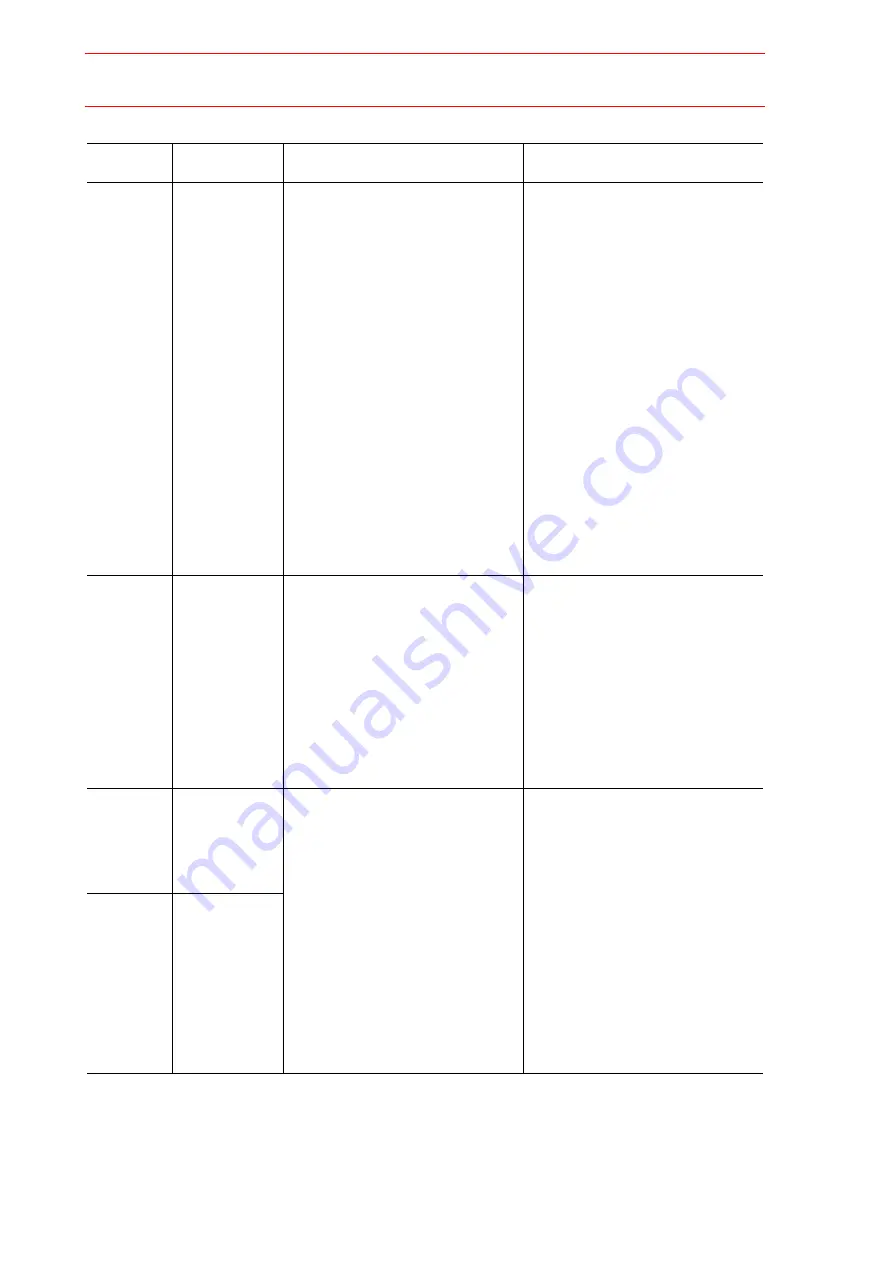

Err701

Output over-

current

Overcurrent flows in the second-

ary control circuit.

Confirm the following.

• Check that the torch cable or

power cable is not grounded.

• Check that the contact tip does

not contact the workpiece to be

welded. Set the contact tip so

as not to contact the work-

piece, then perform welding.

• Check that the encoder cable is

not damaged.

• Check if the screws of the con-

nector terminal block are

securely fastened. If the

encoder cable is disconnected

or the screws are loosened, the

wire feeding speed becomes

excessively fast and an error

occurs in the wire feeding

amount. Replace the encoder

cable or fasten the screws of

the connector terminal block.

Err702

Voltage

detection wire

error

The welding voltage is not

detected.

• Check if the voltage detection

wire is connected. Check if the

voltage detection line or the

short-circuit cap is connected to

the connector CON7.

• Check that the contact tip does

not contact the workpiece to be

welded. Set the contact tip so

as not to contact the workpiece.

• Temporary power failure may

have occurred.

Err790

Outside of

output cur-

rent setting

(Over the

upper limit)

The actual welding current

becomes far removed from the

welding current command value.

• Check if the selection of motor

is correct, or confirm the set-

tings of C parameter C09.

• Check that the welding wire

does not slip, or the wire is fed

as instructed by the feeding

command.

• Check that the wire stickout is

not excessively short or long.

• Check that the range set in C

parameter C29 is not too nar-

row.

• Check if the wire, shielding gas,

welding type, earthing, etc. are

correctly set.

Err791

Outside of

output cur-

rent setting

(Over the

lower limit)

Table. 5 List of Error Display Contents

Error No.

Item

Contents

Remedy

62/129