5.2 Ratings and Specifications

5.2.2 Ratings

5-6

5.2.2

Ratings

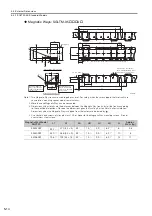

*1.

These values are for operation in combination with a SERVOPACK when the temperature of the armature winding is 100

°

C. The values

for other items are at 20

°

C. These are typical values.

*2.

The rated forces are the continuous allowable force values at a surrounding air temperature of 40

°

C with an aluminum heat sink of the

dimensions given in the following table.

•

Heat Sink Dimensions

•

254 mm

×

254 mm

×

25 mm: SGLTW-20A170A and -35A170A

•

400 mm

×

500 mm

×

40 mm: SGLTW-20A320A, -20A460A, -35A170H, -35A320A, -35A320H, -35A460A,

and -50A170H

•

609 mm

×

762 mm

×

50 mm: SGLTW-40A400B, -40A600B, -50A320H, -80A400B, and -80A600B

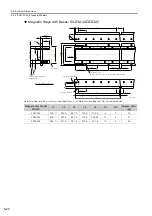

*3.

The unbalanced magnetic gap that results from the Moving Coil installation condition causes a magnetic attraction on the Moving Coil.

*4.

The value that is given is the magnetic attraction that is generated on one side of the Magnetic Way.

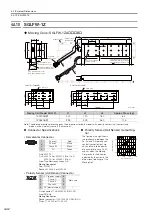

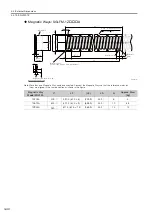

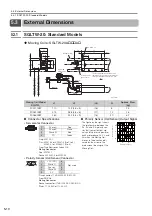

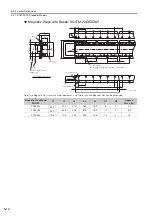

Linear Servomotor Moving

Coil Model SGLTW-

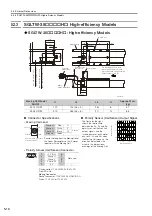

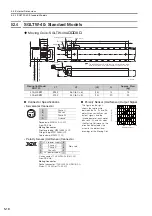

Standard Models

High-efficiency

Models

20A

35A

40A

80A

35A

50A

170A

320A

460A

170A

320A

460A

400B 600B

400B

600B 170H 320H 170H 320H

Rated Motor Speed

(Reference Speed during

Speed Control)

*1

3.0

3.0

3.0

2.5

2.5

2.5

1.5

2.0

2.0

2.0

2.5

2.0

2.0

2.0

Maximum

Speed

*1

m/s

5.0

5.0

5.0

5.0

5.0

5.0

3.1

3.1

2.5

2.5

4.8

4.8

3.2

3.1

Rated Force

*1, *2

N

130

250

380

220

440

670

670

1000

1300

2000

300

600

450

900

Maximum Force

*1

N

380

760

1140

660

1320

2000

2600

4000

5000

7500

600

1200

900

1800

Rated Current

*1

Arms

2.3

4.4

6.7

3.5

7.0

10.7

7.3

10.9

11.1

17.1

5.1

10.1

5.1

10.2

Maximum

Current

*1

Arms

7.7

15.4

23.2

12.1

24.2

36.7

39.4

60.6

57.9

86.9

11.9

23.9

11.8

23.6

Moving Coil Mass

kg

2.5

4.6

6.7

3.7

6.8

10

15

23

24

35

4.9

8.8

6.0

11

Force Constant

N/Arms

61.0

61.0

61.0

67.5

67.5

67.5

99.1

99.1

126

126

64.0

64.0

95.2

95.2

BEMF Constant

Vrms/

(m/s)/

phase

20.3

20.3

20.3

22.5

22.5

22.5

33.0

33.0

42.0

42.0

21.3

21.3

31.7

31.7

Motor Constant

N/

18.7

26.5

32.3

26.7

37.5

46.4

61.4

75.2

94.7

116

37.4

52.9

48.6

68.7

Electrical Time

Constant

ms

5.9

5.9

5.9

6.9

6.8

6.9

15

15

17

17

15

16

16

17

Mechanical Time

Constant

ms

7.1

6.6

6.4

5.2

4.8

4.6

4.0

4.1

2.7

2.6

3.5

3.1

2.5

2.4

Thermal

Resistance

(with Heat Sink)

K/W

1.01

0.49

0.38

0.76

0.44

0.32

0.24

0.20

0.22

0.18

0.76

0.40

0.61

0.30

Thermal

Resistance

(without Heat

Sink)

K/W

1.82

1.11

0.74

1.26

0.95

0.61

0.57

0.40

0.47

0.33

1.26

0.83

0.97

0.80

Magnetic Attrac-

tion

*3

N

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Magnetic

Attraction on

One Side

*4

N

800

1590

2380

1400

2780

4170

3950

5890

7650

11400

1400

2780

2000

3980

Maximum Allow-

able Payload

kg

25

50

76

44

88

130

280

440

690

1000

33

67

92

190

Maximum Allow-

able Payload

(With External

Regenerative

Resistor and

External Dynamic

Brake Resistor)

kg

25

50

76

44

88

130

280

440

690

1000

40

82

95

190

Combined Magnetic Way,

SGLTM-

20

A

35

A

40

A

80

A

35

H

50

H

Combined Serial Converter

Unit, JZDP-

-

011

012

013

014

015

016

185

186

187

188

105

106

108

109

Applicable

SERVOPACKs

SGD7S-

3R8A

7R6A

120A

5R5A

120A

180A

330A

550A

5R5A

120A

5R5A

120A

SGD7W-

SGD7C-

5R5A

7R6A

−

5R5A

−

5R5A

−

5R5A

−

W