9 Troubleshooting

9.1.1 List of Alarms

9-2

9.1

Alarm Displays

The following sections describe troubleshooting in response to alarm displays.

The alarm name, alarm meaning, alarm stopping method, alarm code output, and alarm reset capability are

listed in order of the alarm numbers in

9.1.1 List of Alarms

.

The causes of alarms and troubleshooting methods are provided in

9.1.2 Troubleshooting of Alarms

.

9.1.1

List of Alarms

This section provides list of alarms.

Servomotor Stopping Method

If an alarm occurs, the servomotor can be stopped by doing either of the following operations.

Gr.1: The servomotor is stopped according to the setting in Pn001.0 if an alarm occurs. Pn001.0 is factory-set

to stop the servomotor by applying the DB.

Gr.2: The servomotor is stopped according to the setting in Pn00B.1 if an alarm occurs. Pn00B.1 is factory-set

to stop the servomotor by setting the speed reference to

"

0.

"

The servomotor under torque control will

always use the Gr.1 method to stop. By setting Pn00B.1 to 1, the servomotor stops using the same

method as Gr.1. When coordinating a number of servomotors, use this stopping method to prevent

machine damage that may result due to differences in the stop method.

Alarm Reset

Available: Removing the cause of alarm and then executing the alarm reset can clear the alarm.

N/A: Executing the alarm reset cannot clear the alarm.

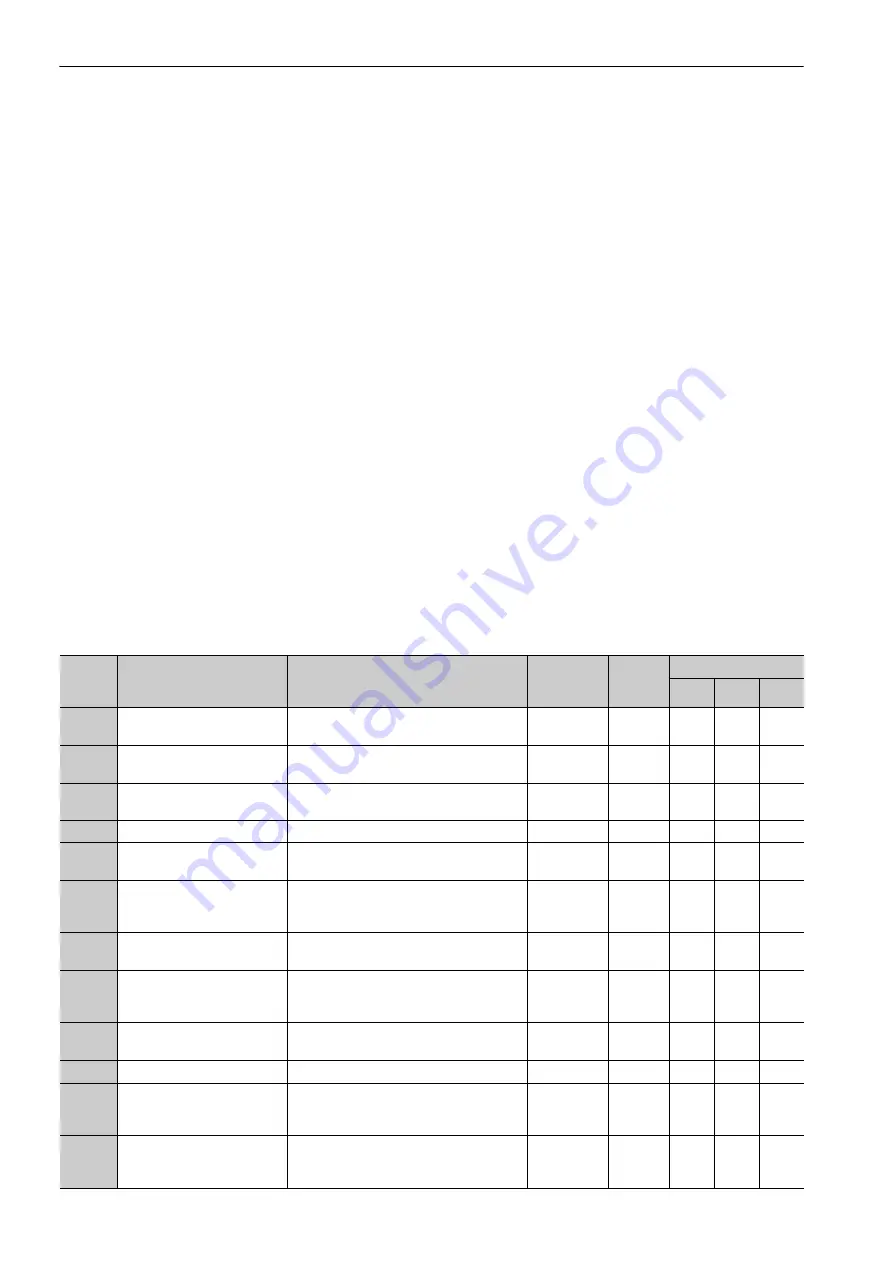

Alarm

Number

Alarm Name

Meaning

Servomotor

Stopping

Method

Alarm

Reset

Alarm Code Output

ALO1 ALO2 ALO3

A.020

Parameter Checksum

Error 1

The data of an internal parameter in the

multi-winding drive unit is incorrect.

Gr.1

N/A

H

H

H

A.021

Parameter Format Error 1

The data type of an internal parameter in

the multi-winding drive unit is incorrect.

Gr.1

N/A

H

H

H

A.022

System Checksum Error 1

The data of an internal parameter in the

multi-winding drive unit is incorrect.

Gr.1

N/A

H

H

H

A.030

*

Main Circuit Detector Error

Detection data for main circuit is incorrect.

Gr.1

Available

H

H

H

A.040

Parameter Setting Error 1

The parameter setting is outside the setting

range.

Gr.1

N/A

H

H

H

A.041

Encoder Output Pulse

Setting Error

The encoder output pulse (Pn212) is out-

side the setting range or does not satisfy

the setting conditions.

Gr.1

N/A

H

H

H

A.042

Parameter Combination

Error

Combination of some parameters exceeds

the setting range.

Gr.1

N/A

H

H

H

A.045

Multi-winding Drive Unit

Parameter Setting Error

The parameter setting does not match the

number of SERVOPACK axes that are

connected.

Gr.1

N/A

H

H

H

A.050

Combination Error

The SERVOPACK and the servomotor

capacities do not match each other.

Gr.1

Available

H

H

H

A.051

Unsupported Device Alarm

The device unsupported was connected.

Gr.1

N/A

H

H

H

A.0b0

Cancelled Servo ON

Command Alarm

The servo ON signal (/S-ON) was sent

from the host controller after executing a

utility function that turns ON servomotor.

Gr.1

Available

H

H

H

A.100

*

Overcurrent or Heat Sink

Overheated

An overcurrent flowed through the IGBT

or the heat sink of the SERVOPACK was

overheated.

Gr.1

N/A

L

H

H