3 Electrical Installation

YASKAWA Europe

TOEP_C710606_97A - AC Drive A1000 IP54READY - Quick Start Guide

EN 13

Wiring Specification

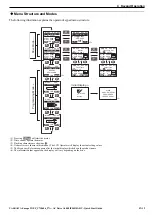

Main Circuit

Use the fuses and line filters listed in the table below when wiring the main circuit. Make sure not to exceed the given

tightening torque values.

Tightening Torque Values

Tighten the main circuit terminals using the torque values provided by the table below.

Control Circuit

The control terminal board is equipped with screwless terminals. Always use wires within the specification listed below.

For safe wiring it is recommended to use solid wires or flexible wires with ferrules. The stripping length respectively

ferrule length should be 8 mm.

EMC Filter Installation

This drive has been tested in accordance with European standards EN61800-3. In order to comply to the EMC standards,

wire the main circuit as described below.

1. Install an appropriate EMC noise filter to the input side. See the table in

Technical Manual for details.

2. Place the drive and EMC noise filter in the same enclosure.

3. Use braided shield cable for the drive and motor wiring.

4. Remove any paint or dirt from ground connections for minimal ground impedance.

5. Prepare braided ground strap with ring terminal to ensure proper EMC grounding from the drive to the panel.

6. Use M6 stud on drives mounting frame to connect with braided ground strap to metal mounting plate of the panel.

7. Keep this EMC grounding braided strap as short as possible.

Model

CIMR-A

EMC Filter

[Block]

Main Fuse

[Bussmann]

Recom.

Motor cable

(mm

2

)

Main Circuit Terminal Sizes

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

– , +1, +2

+3

B1, B2

4A0044

FB-40060A

FWH-250A

16

M6

–

M5

M8

4A0058

M8

M8

4A0072

FB-40072A

25

4A0088

FB-40105A

M10

–

4A0103

35

4A0139

FB-40170A

FWH-350A

50

M10

M10

4A0165

FWH-400A

70

Terminal Size

M5

M6

M8

M10

Tightening Torque (N

m)

2.0 to 2.5

4.0 to 6.0

9.0 to 11.0

18.0 to 23.0

Wire Type

Wire size (mm

2

)

Solid

0.2 to 1.5

Flexible

0.2 to 1.0

Flexible with ferrule

0.25 to 0.5