3 - 1

CHK

ADJ

EAS00036

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjustments.

If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a

longer service life and reduce the need for costly overhaul work. This information applies to vehicles

already in service as well as to new vehicles that are being prepared for sale. All service technicians

should be familiar with this entire chapter.

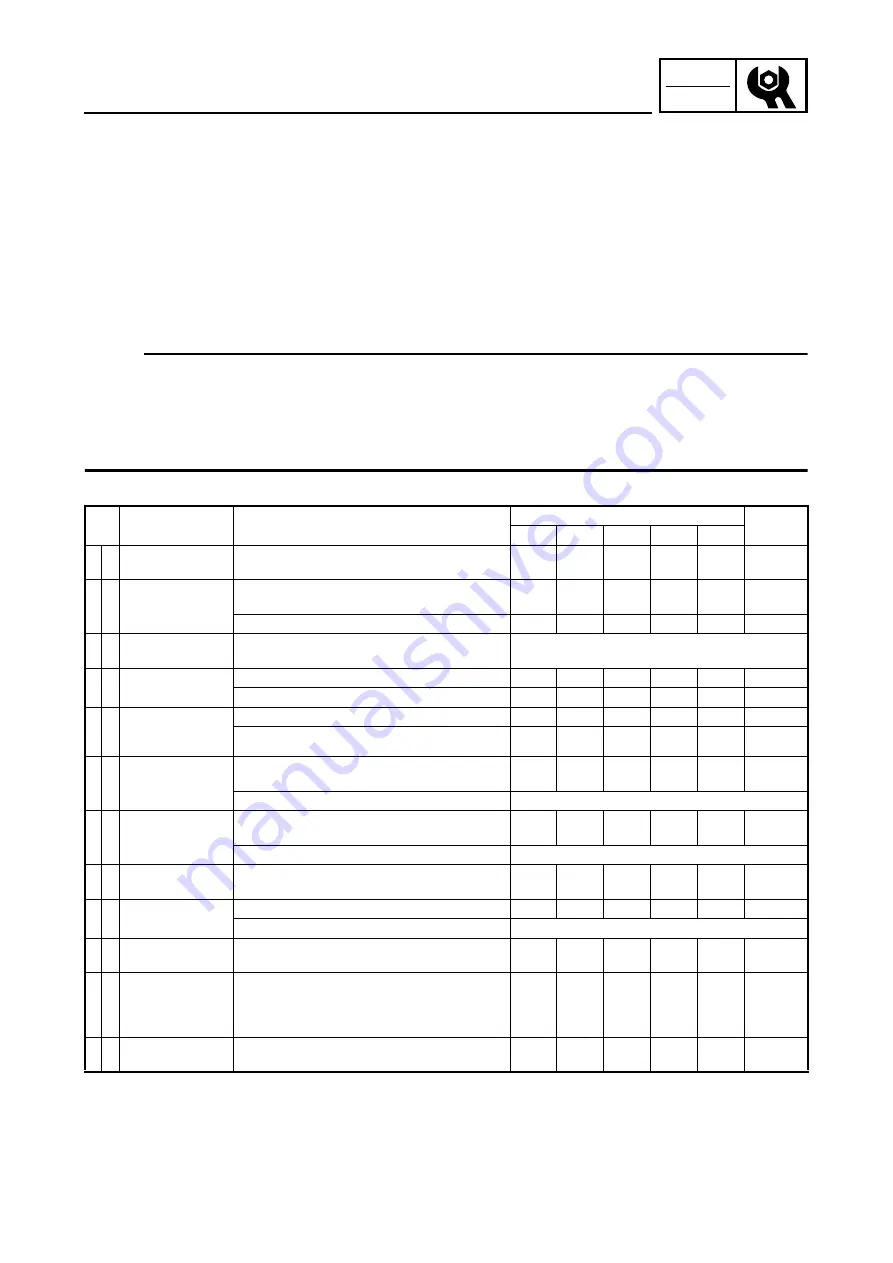

PERIODIC MAINTENANCE AND LUBRICATION CHART

NOTE:

• The annual checks must be performed every year, except if a kilometer-based maintenance

is performed instead.

• From 50000 km, repeat the maintenance intervals starting from 10000 km.

• Items marked with an asterisk should be performed by a Yamaha dealer as they require special

tools, data and technical skills.

NO.

ITEM

CHECK OR MAINTENANCE JOB

ODOMETER READING (

×

1000 km)

ANNUAL

CHECK

1

10

20

30

40

1

*

Fuel line

(See page 3-37.)

• Check fuel hoses for cracks or damage.

√

√

√

√

√

2

Spark plugs

(See page 3-25.)

• Check condition.

• Clean and regap.

√

√

• Replace.

√

√

3

*

Valves

(See page 3-11.)

• Check valve clearance.

• Adjust.

Every 40000 km

4

Air filter element

(See page 3-34.)

• Clean.

√

√

• Replace.

√

√

5

*

V-belt case air fil-

ter elements

(See page 3-35.)

• Clean.

√

√

• Replace.

√

√

6

*

Front brake

(See page 3-47,

3-48.)

• Check operation, fluid level and vehicle for fluid

leakage.

√

√

√

√

√

√

• Replace brake pads.

Whenever worn to the limit

7

*

Rear brake

(See page 3-47,

3-48.)

• Check operation, fluid level and vehicle for fluid

leakage.

√

√

√

√

√

√

• Replace brake pads.

Whenever worn to the limit

8

Rear brake lock

(See page 3-46.)

• Check operation.

• Adjust.

√

√

√

√

√

√

9

*

Brake hoses

(See page 3-48.)

• Check for cracks or damage.

√

√

√

√

√

• Replace.

Every 4 years

10 *

Wheels

(See page 3-59.)

• Check runout and for damage.

√

√

√

√

11 *

Tires

(See page 3-57.)

• Check tread depth and for damage.

• Replace if necessary.

• Check air pressure.

• Correct if necessary.

√

√

√

√

√

12 *

Wheel bearings

(See page 4-8.)

• Check bearing for looseness or damage.

√

√

√

√

INTRODUCTION/

PERIODIC MAINTENANCE AND LUBRICATION CHART

Содержание XP500

Страница 1: ...2005 XP500 XP500A5VU5 AE1 SERVICE MANUAL...

Страница 2: ......

Страница 8: ......

Страница 9: ...GEN INFO 1...

Страница 11: ...GEN INFO...

Страница 38: ...SPEC 2...

Страница 40: ...SPEC...

Страница 68: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Oil strainer 2 Crankshaft...

Страница 69: ...2 29 SPEC OIL FLOW DIAGRAMS 1 Clutch 2 Right main journal bearing 3 Main gallery plug...

Страница 118: ......

Страница 119: ...CHK ADJ 3...

Страница 193: ......

Страница 194: ...CHAS 4...

Страница 198: ...CHAS...

Страница 292: ...4 94 CHAS ANTI LOCK BRAKE SYSTEM XP500A...

Страница 326: ......

Страница 327: ...ENG 5...

Страница 331: ...ENG...

Страница 421: ...5 90 ENG Order Job Part Q ty Remarks C Retainer 1 For assembly reverse the disassembly procedure CHAIN DRIVE...

Страница 424: ...COOL 6...

Страница 426: ...COOL...

Страница 442: ......

Страница 443: ...FI 7...

Страница 445: ...FI...

Страница 476: ...ELEC 8...

Страница 544: ......

Страница 545: ...TRBL SHTG 9...

Страница 553: ......

Страница 556: ......

Страница 557: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN...