is easily felt. This feel for the equipment produces

consistently accurate measurements and reduces

the risk of damaging the tool or component. Refer to

the following sections for a description of various

measuring tools.

Feeler Gauge

The feeler or thickness gauge (

Figure 26

) is used

for measuring the distance between two surfaces. A

common use for a feeler gauge is to measure valve

clearance. Wire (round) type gauges are used to

measure spark plug gap.

A feeler gauge set consists of an assortment of

steel strips of graduated thicknesses. Each blade is

marked with its thickness. Blades can be of various

lengths and angles for different procedures.

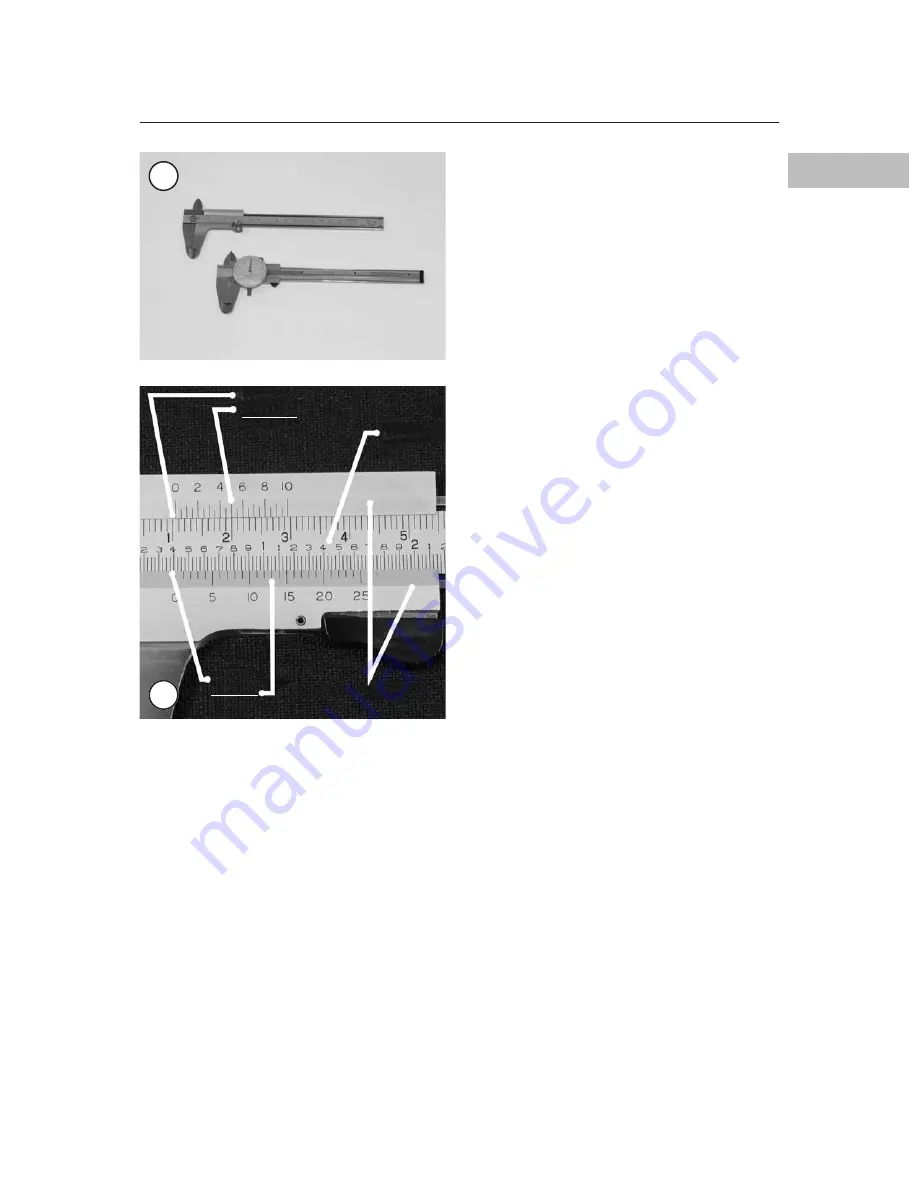

Calipers

Calipers (

Figure 27

) are excellent tools for ob-

taining inside, outside and depth measurements. Al-

though not as precise as a micrometer, they allow

reasonable precision, typically to within 0.05 mm

(0.001 in.). Most calipers have a range up to 150

mm (6 in.).

Calipers are available in dial, vernier or digital

versions. Dial calipers have a dial, which is easy to

read. Vernier calipers have marked scales that must

be compared to determine the measurement. The

digital caliper uses an LCD display to show the

measurement.

Properly maintain the measuring surfaces of the

caliper. There must not be any dirt or burrs between

the tool and the object being measured. Never force

the caliper closed around an object. Close the cali-

per around the highest point so it can be removed

with a slight drag. Some calipers require calibra-

tion. Always refer to the manufacturer’s instruc-

tions when using a new or unfamiliar caliper.

Figure 28

shows a measurement taken with a

metric vernier caliper. To read the measurement,

note that the fixed scale is graduated in centimeters,

which is indicated by the whole numbers 1, 2, 3 and

so on. Each centimeter is then divided into millime-

ters, which are indicated by the small line between

the whole numbers. (1 centimeter equals 10 milli-

meters). The movable scale is marked in increments

of 0.05 (hundredths) mm. The value of a measure-

ment equals the reading on the fixed scale plus the

reading on the movable scale.

To determine the reading on the fixed scale, look

for the line on the fixed scale immediately to the left

of the 0-line on the movable scale. In

Figure 28

, the

fixed scale reading is 1 centimeter (or 10 millime-

ters).

To determine the reading on the movable scale,

note the one line on the movable scale that precisely

aligns with a line on the fixed scale. Look closely. A

number of lines will seem close, but only one aligns

precisely with a line on the fixed scale. In

Figure

28

, the movable scale reading is 0.50 mm.

To calculate the measurement, add the fixed scale

reading (10 mm) to the movable scale reading (0.50

mm) for a value of 10.50 mm.

GENERAL INFORMATION

15

1

27

28

10.00 mm

0.50 mm

10.50 mm

Moveable scales

Fixed

scale

0.400 in

.

0.013 in.

0.413 in.