combustible dust, fibers, or paper and remove any for-

eign materials. Contact your local Yale dealer for forklift

modifications that may be appropriate in environments

with fire hazards.

Operate the lift truck only in areas that have been

approved for lift truck operation.

• OSHA regulations prohibit the use of lift trucks in

areas containing hazardous concentrations of certain

flammable gases or vapors.

• OSHA regulations require operating areas to be clas-

sified as hazardous or nonhazardous, and that the lift

trucks used in designated locations be of the mini-

mum type specified (see Guide For Users Of Industrial

Trucks, Appendix C and Table N-1).

Only the designated types of approved lift trucks may be

used in areas classified as hazardous by the authority

having jurisdiction. Areas classified as hazardous must

be identified by signs to show the type of approved lift

truck required for operation in the area. Modifications or

poor maintenance can result in the lift truck being

unsuitable for operation in areas classified as hazard-

ous.

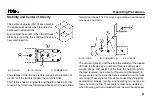

The fork lift truck is designed to pickup, move, and tier mate-

rials. The basic lift truck has a lift mechanism and forks on

the front to engage the load. The lift mechanism lifts the load

so that it can be moved and stacked.

In order to understand how the fork lift truck can pick up a

load, you must first know some basic things about the lift

truck.

The lift truck is based on the principle of two weights balanced

on opposite sides of a pivot (fulcrum). This is the same prin-

ciple used for a see-saw. In order for this principle to work for

a lift truck, the load on the forks must be balanced by the

weight of the lift truck. The location of the center of gravity of

both the truck and the load is also a factor.

This basic principle is used for picking up a load. The ability

of the lift truck to handle a load is discussed in terms of center

of gravity and both forward and side stability.

Operating Procedures

60

Содержание GDP040-070VX

Страница 81: ...Figure 12 Seat Adjustment Full Suspension Operating Procedures 79 ...

Страница 112: ...1 DRIVE TIRES 2 STEERING TIRES Figure 16 Put a Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 110 ...

Страница 113: ...Figure 17 Kubota 2 5L LPG Engine Maintenance and Lubrication Points Maintenance Schedule 111 ...

Страница 114: ...Figure 18 PSI 2 4L Dual Fuel Engine Maintenance and Lubrication Points Maintenance Schedule 112 ...

Страница 115: ...Figure 19 Yanmar 2 6L and 3 3L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 113 ...

Страница 116: ...Figure 20 Kubota 2 4L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 114 ...

Страница 169: ...Figure 37 LPG Tank and Bracket Maintenance 167 ...

Страница 203: ...Spacer 5 15 4 15 2 15 1 15 11 14 ...