WARNING

Do not use a steel hammer on the wheel. Use a rubber,

lead, plastic, or brass hammer to put parts together.

WARNING

Do not lubricate the tire bead with antifreeze or petro-

leum-based liquid. Vapors from these liquids can cause

an explosion during inflation or use.

WARNING

DO NOT mix brands of rubber sealing rings and tires.

Serious injury to personnel or damage to the lift truck

can occur if the rubber sealing rings are not compatible

with the tire brand.

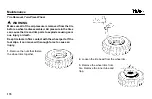

1.

Clean interior and exterior

bead area of the tire. Lubri-

cate tire beads and the

inside of the tire, up to the

tire shoulders. Apply lubri-

cant to entire underside of

the TBS or TSR. Use lubri-

cant approved by the tire

manufacturer.

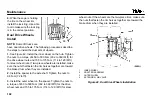

NOTE:

If the wheel rim width

is less than six inches, the TBS will contain one valve hole to

accommodate the needle valve. If the wheel rim width is

greater than six inches, the TBS will have two holes for the

needle valve.

One hole is centrally located and the other is offset, to ensure

the correct positioning of the valve in the valve slot. The valve

hole that is not used should be sealed with a small plastic

plug.

Maintenance

185

Содержание GDP040-070VX

Страница 81: ...Figure 12 Seat Adjustment Full Suspension Operating Procedures 79 ...

Страница 112: ...1 DRIVE TIRES 2 STEERING TIRES Figure 16 Put a Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 110 ...

Страница 113: ...Figure 17 Kubota 2 5L LPG Engine Maintenance and Lubrication Points Maintenance Schedule 111 ...

Страница 114: ...Figure 18 PSI 2 4L Dual Fuel Engine Maintenance and Lubrication Points Maintenance Schedule 112 ...

Страница 115: ...Figure 19 Yanmar 2 6L and 3 3L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 113 ...

Страница 116: ...Figure 20 Kubota 2 4L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 114 ...

Страница 169: ...Figure 37 LPG Tank and Bracket Maintenance 167 ...

Страница 203: ...Spacer 5 15 4 15 2 15 1 15 11 14 ...