5.

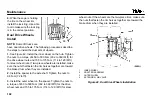

For TBS, with separate

valve stems, place the wheel

and tire assembly on a flat sur-

face. Turn the valve a 1/4 turn

to lock the collar under the

edges of the rim valve slot.

6.

Raise the tire and position

the base and threaded stem of

the press through the hole in

the center of the wheel. Insert

in wheel assembly, the follow-

ing parts:

•

Advance band (four-piece

wheel only)

•

Loose flange

•

Locking ring

7.

Position the advance band.

Ensure that it does not go in

too far and damage the valve.

Position the arms of the press

onto the loose flange.

CAUTION

DO NOT compress the bead

too far and cause the rubber

sealing ring to become dis-

torted and damage the valve

stem.

Push down on press to

depress the tire beads until the

locking ring groove is fully

exposed.

8.

Insert tire tool into the lock-

ing ring groove, and a vise grip

on other end. Remove vise

grip. Release the press and

check that all component parts

are correctly positioned.

Replace the valve core.

9.

Inflate tire to 103 kPa

(15 psi). Tap wheel with a mal-

let to ensure all components

are correctly sealed. Remove the press from wheel and tire

assembly.

Maintenance

187

Содержание GDP040-070VX

Страница 81: ...Figure 12 Seat Adjustment Full Suspension Operating Procedures 79 ...

Страница 112: ...1 DRIVE TIRES 2 STEERING TIRES Figure 16 Put a Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 110 ...

Страница 113: ...Figure 17 Kubota 2 5L LPG Engine Maintenance and Lubrication Points Maintenance Schedule 111 ...

Страница 114: ...Figure 18 PSI 2 4L Dual Fuel Engine Maintenance and Lubrication Points Maintenance Schedule 112 ...

Страница 115: ...Figure 19 Yanmar 2 6L and 3 3L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 113 ...

Страница 116: ...Figure 20 Kubota 2 4L Diesel Engine Maintenance and Lubrication Points Maintenance Schedule 114 ...

Страница 169: ...Figure 37 LPG Tank and Bracket Maintenance 167 ...

Страница 203: ...Spacer 5 15 4 15 2 15 1 15 11 14 ...