-20-

M1012 48" Pan and Box Brake

O

PE

R

AT

O

N

S

Basic Bending

Bending operations require the fingers to be parallel with

the edge of the clamping block and require the setback

and clamping pressure to be correctly adjusted for the

thickness of the workpiece.

To perform a basic bending operation, do these steps:

1.

Lift the clamping handle to open the clamping leaf

all the way.

2.

Insert the workpiece between the fingers and the

clamping block.

3.

Align the fingers of the clamping leaf to the bend

mark on the workpiece, and clamp it in place.

Note

: Do not force the clamping handle. If the han-

dle is hard to put in the locked position, the pres-

sure may need to be adjusted for the sheet metal

thickness. The holding pressure of the clamping

leaf needs to be just tight enough to hold the sheet

metal from moving when bending.

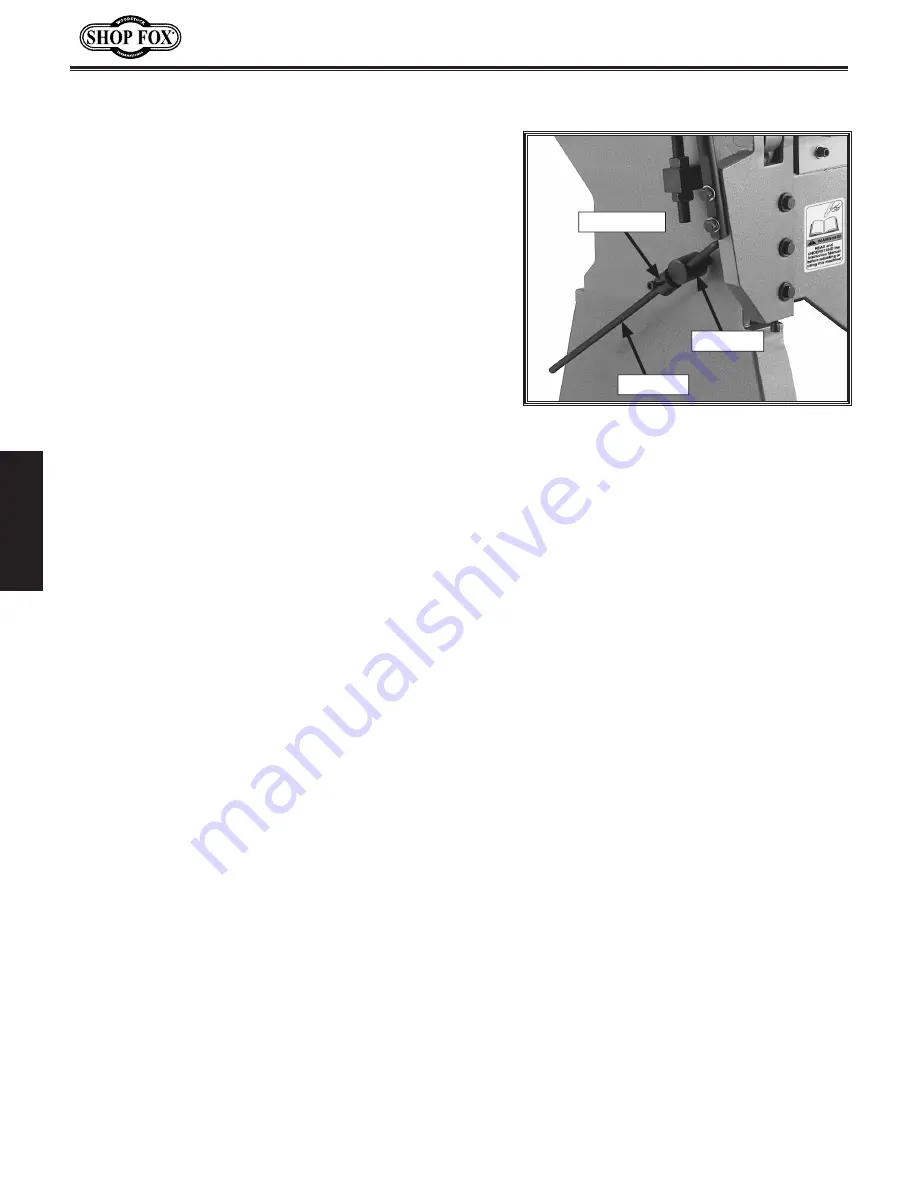

Setting Stop Collar

The stop collar (

Figure 25

) limits the amount that the

bending leaf can travel during bending, thereby allowing

you to repeat a bend at an exact angle.

To use the stop collar, do these steps:

1.

Completely loosen the stop collar.

2.

Make the bend that you want to repeat and hold the

bending leaf in place at the top of the bend.

3.

Slide the stop collar up against the stop hub and

tighten it in place (

Figure 25

).

4.

Check the stop collar by lowering the bending leaf

and then raising the bending leaf into a bend. If the

stop is working correctly, the bending leaf will stop

in the same position as the first bend.

Figure 25.

Stop collar shown tightened

against stop hub on stop rod.

Stop Collar

Stop Hub

Stop Rod

Содержание SHOP FOX M1012

Страница 2: ......

Страница 28: ... 26 M1012 48 Pan and Box Brake PARTS PARTS ...

Страница 30: ... 28 M1012 48 Pan and Box Brake PARTS PARTS ...

Страница 35: ......

Страница 36: ......