16

OPM-135/C

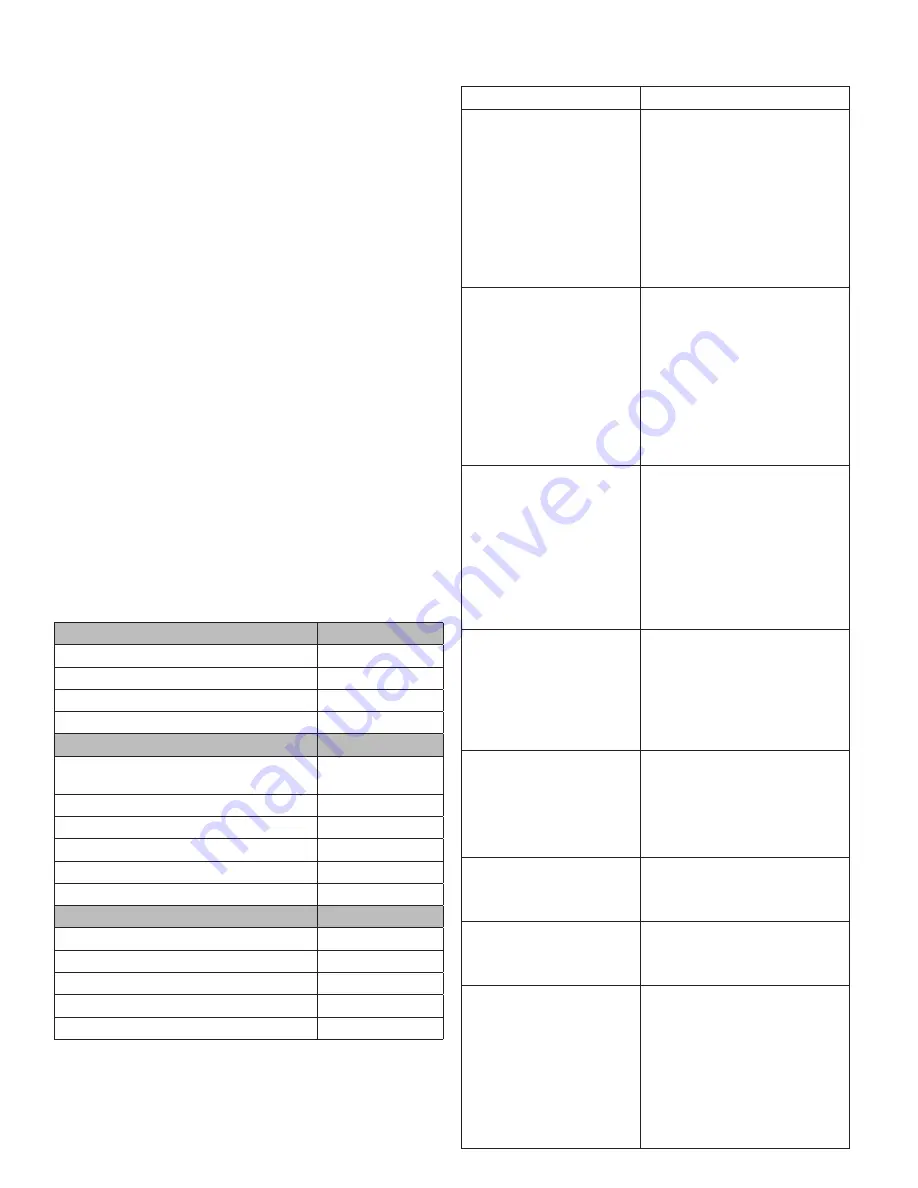

TROUBLESHOOTING TABLE

Problem

Possible Causes

Unit will not crank when

power fails

Digital genset not in AUTO

Transfer control switch not in

AUTOMATIC position

Incorrect wiring between ATS

and genset

Defective control relay in ATS

Fuse(s) blown in the DSE7310

Defective DSE7310

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Low/dead battery

Engine won’t crank

Low/dead battery

Blown DC fuses

Defective DSE7310

Defective key switch

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Locked up engine genset

Defective engine harness

Improper battery voltage to

start solenoid, fuel pump, or

fuel solenoid

Engine cranks but will not

start

Improper fuel delivery to the unit

Fuel supply shut off

Fuel tank empty

Air in the fuel system

Engine fuel solenoid has not

opened

Defective fuel pump

Defective fuel solenoid

Defective engine harness

Improper battery voltage to fuel

pump or fuel solenoid

Engine starts, then stops and

alarm light comes on

Engine oil pressure is low

Engine has high water

temperature

Engine has overspeed

Engine has gone into overcrank

No output from AC generator

Loss of speed signal

Loss of run signal

Engine will not come up to

speed after it starts

Insufficient fuel volume getting to

the unit

1. Too small of fuel line

2. Fuel racks not open properly

Governor is defective

AC short in generator

components

ATS will not transfer

to Emergency Supply

(generator)

No AC generator output

Defective ATS control board.

See ATS manual

Circuit breaker open or defective

ATS will not re-transfer to

normal power

Proper power line not available at

line terminals in ATS panel

Defective ATS control board.

See ATS manual

No AC output from generator Defective diode

Defective voltage regulator

Defective rotor

Defective stator

Defective exciter rotor

Defective exciter stator

AC short in the output leads

Defective/open generator output

breaker

Wiring error

protective liquid (ISO 4113) and introduce the liquid by

pressurizing the circuit and driving the engine for

approx. 2 min. after excluding injection system

operation.

The operation required can be completed by directly

polarizing terminal 50 of the electric starter motor with

positive voltage equal to that of the nominal system voltage,

using the designated conductor.

5. Nebulize the 30/M protective oil in a quantity of

approx. 130 g (10 g per liter of displacement) in the

turbocharger intake inlet, during the engine turning

operation described in the previous paragraph.

6. Close all of the engine’s intake, discharge, ventilation

and bleeding holes with plugs or seal them with

adhesive

tape.

7. Drain the residual 30/M protective oil from the sump,

which can be used for an additional 2 preparations.

8. Place warning notices of ENGINE WITHOUT OIL on the

engine and dashboard.

NOTE: When storing in cold regions, make sure the

coolant and engine oil are in conditions suitable to the

environment. Also, when starting the engine after it has

been stored, make sure that there is no snow or foreign

matter that could interfere with engine startup, and

rotating parts are not frozen.

MAINTENANCE SCHEDULE

Checks In Period of Use

Frequency

Check for water in the fuel filter

Daily

Check Air-Restriction Indicator on Filter Daily

Engine Oil Level

Daily/Prior to Use

Engine Coolant Level

Daily/Prior to Use

Planned Maintenance

Frequency

Tension and Condition Check of

Ancillary Belt

500 Hours

Engine Oil Replacement

250 Hours

Oil Filter Replacement

500 Hours

Fuel Filter Replacement

500 Hours

Clean Radiator

500 Hours

Air Filter Replacement

1250 Hours

Extraordinary Maintenance

Frequency

Ancillary Belt Replacement

3000 Hours

Turbocharger Visual Inspection

1500 Hours

Alternator Visual Inspection

3000 Hours

Clean/Replace Radiator Cap

3000 Hours

Engine Coolant Replacement

3000 Hours

NOTE: Some operating conditions may require more

frequent maintenance intervals.

Содержание DR20I4-/1 Series

Страница 18: ...18 OPM 135 C DSE7310 WIRING DIAGRAM...