DISPLA

Y

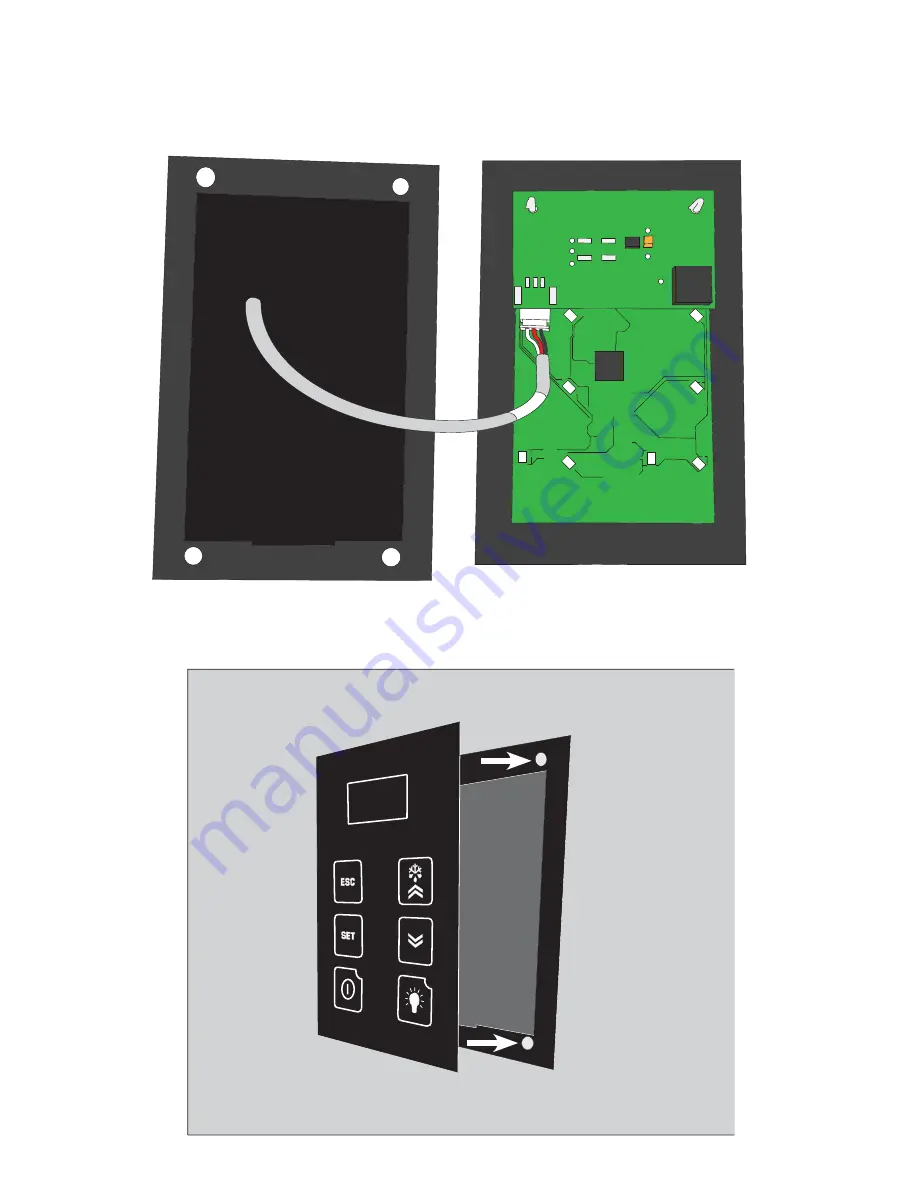

7. Connect the end of the display cable to the JST connector on the display panel.

BRACKET

DISPLAY

8. Place the display on th

e fl

ush mount bracket as shown, attaching the back of the display panel to the magnets on

the mounting bracket. Make sure that the alignment tab on the back of the display panel sits in the notch on the bot-

tom of the bracket.

FLUSH MOUNT BRACKET INSTALLATION, CONTINUED

WALL

Page 26

08/04/21