TY P E S I R P, I R C A�D IRD R E LAYS

P o D IDENTIFYING

2

DOT

POSITION

RATED D - C

L E AD

0

VOLT AGE

4 6

1 2 5

250

RESISTOR

R E SI STANCE

0

300

2700

6500

NOTE

RELAYS ARE S H I P P E D O N T H E

125

VOLT TAP

L E A D

@

184A316

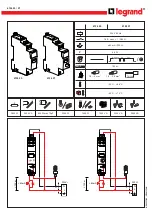

Fig. 23. Sele ction o f Proper Voltage Tap for A u xi li ary

Switch ( CS- 1) Operation.

screwed in completely and the other plug run in or

out until the proper operating time has been obtained.

Recheck the permanent magnet adjustment. If the

operating time for this c alibration point has changed,

readjust the permanent m agnet and then recheck the

electromagnet plug adjustment.

Contactor Switches

and

Adjust the contact gap for approximately .04

7".

A) Close the contacts of the C O and pass suf-

B) Close contacts of instantaneous overcurrent

unit

(I)

and directional unit (D). Pass sufficient d. c.

current through the trip circuit to close contacts of the

(ICS/1). This value of current should hot be greater

than the particular (ICS/1) tap setting being used.

The operation indicator target should drop freely

bringing the letter "I " into view.

A u x i l i ary Switch

Adjust the stationary core of the switch for a

clearance between the stationary core and the moving

core when the switch is picked up . This can be done

by turning the relay upside-down. Then screw up the

core screw until the moving core starts rotating. Now

back off the core screw until the moving core stops

rotating.

This indicates the points where the play

in the assembly is taken up, and where the moving

core just separates from the stationary core screw.

Back off the core screw approximately one turn and

lock in place. This prevents the moving core from

striking and sticking to the stationary core because

of residual magnetism. Adjust the contact clearance

for 3/64 " by means of the two small nuts on either

side of the Micarta disc.

Connect lead (A) to proper terminal per Fig.

23 .

Block directional unit (D) contacts

clo se and ener

gize trip circuit with rated voltage .

Contacts of

auxiliary switch (CS- 1 ) should make as indicated by

a neon lamp in the contact circuit.

R EN E WA L PA R T S

ficient d. c. current through the trip circuit to close

Repair work can be done most satisfactorily at

the contacts of the (ICS/T). This value of current

the factory. However, interchangeable parts can be

should not be greater than the particular (ICS/T) tap

furnished to the customers who are e quipped for doing

setting being used. The operation indicator target

repair work .

When ordering parts, always give the

should drop freely bringing the letter "T" into view.

complete nameplate data.

TAB L E I

D I R ECT IO�AL UNIT SENSITIVITY

AM P E R E RATI NG

R E LAY TY P E

O F

VAL U ES F O R MI N. P I CKUP

t

PHASE ANG L E R E LAT I ONSH I P

TIM E-O V E RCU R R E N T

U N I T

VOLTS

AMP E R E S

. 5-2. 5

1

2

. 0

IRP

2-6

1

4 . 0

IRD (Voltage

Unit)

1

4 . 0

4- 1 2

1

8 . 0

0 . 5

. 5- 2. 5

IRC

2-

6

. 5 7

IRD (Current

6

Unit)

4- 1 2

1 . 0

t

The energization

quantities

are

input quantities

at

the relay

terminals.

t t Maximum torque angle.

I lagging V by 60°

T

t

I in-pha� with V

I

lagging V by 60°

t t

I in-phase with V

I 0 leading Ip

In-phase

I0 leading IP

by 40° t t

by 40° t t

6,

When normal system conditions

limit the current to less than twice pickup . performance may b e improved b y sel

lecting a higher current C. T.

tap to energize the polarizing circuit.

27

www

. ElectricalPartManuals

. com